Napoleon HYBRID 150 Mode D'emploi

Masquer les pouces

Voir aussi pour HYBRID 150:

- Instructions d'installation et d'utilisation (184 pages) ,

- Instructions d'installation et d'opération (132 pages)

Table des Matières

Publicité

Liens rapides

CerTified under CAnAdiAn And AmeriCAn nATionAl STAndArdS: ul 391 5

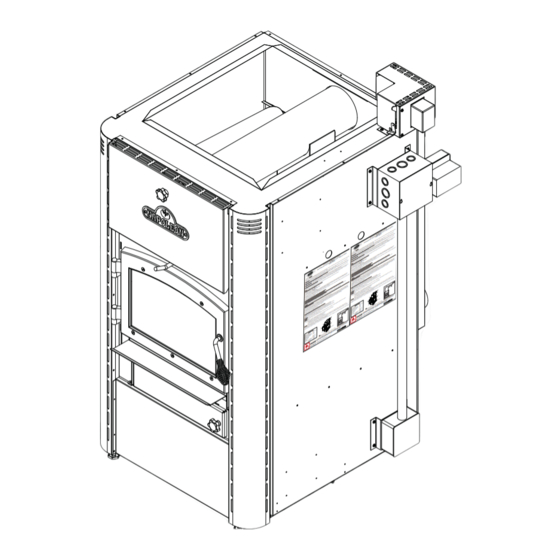

HYBRID 150/200

HMF150/200

MULTI-FUEL FURNACES

SAFETY INFORMATION

WARNING

!

If the information in these instructions are not followed

exactly, a fi re or explosion may result causing property

damage, personal injury or death.

please read entire manual before you install and use your

heater.

- This heater can be very hot when burning.

- Combustible materials such as fi rewood, wet clothing, etc.

placed too close can catch fi re.

- Children and pets must be kept from touching the heater when

it is hot.

- The chimney must be sound and free of cracks. Before

installing this unit, contact the local building or fi re or other

authority having jurisdiction and follow their guidelines.

- Operate only with the doors tightly closed.

- Do not use an elevated grate or otherwise raise the fi re.

- This heater is designed to burn natural wood only. Higher

effi ciencies and lower emissions generally result when

burning air dried seasoned hardwoods, as compared to

softwoods or to green or freshly cut hardwoods.

- Do not start a fi re with chemicals or fl uids such as gasoline,

engine oil, etc.

- Do not burn treated wood, coal, charcoal, coloured paper,

cardboard, solvents or garbage.

- Do not let the heater become hot enough for any part to glow

red.

Phone (705)721-1212 • fax (705)722-6031 • www.napoleonheatingandcooling.com • ask@napoleonheatingandcooling.com

$10.00

INSTALLER: LEAvE THIS MANUAL WITH THE AppLIANCE.

CONSUMER: SAvE THESE INSTRUCTIONS

OpERATINg INSTRUCTIONS

Wolf Steel ltd., 24 napoleon rd., barrie, on, l4m 0G8 Canada /

103 miller drive, Crittenden, kentucky, uSA, 41030

INSTALLATION AND

ed 2010, ul 727 9

ed 2006, CSA b366.1-m91, CSA b140.4-04, CSA b212-00,

th

th

CSA b415.1-10.

AVERTISSEMENT

!

rPT# 415-S-09-2, 415-S-09b-8.3

WARNING

!

HOT GLASS WILL

CAUSE BURNS.

DO NOT TOUCH GLASS

UNTIL COOLED.

NEVER ALLOW CHILDREN

TO TOUCH GLASS.

LA VITRE CHAUDE CAUSERA

DES BRÛLURES.

NE PAS TOUCHER LA VITRE

AVANT QU'ELLE AIT REFROIDI.

NE JAMAIS LAISSER LES

ENFANTS TOUCHER LA VITRE.

1

W415-1013 / A / 06.05.12

Publicité

Table des Matières

Sommaire des Matières pour Napoleon HYBRID 150

- Page 1 AVANT QU’ELLE AIT REFROIDI. NE JAMAIS LAISSER LES ENFANTS TOUCHER LA VITRE. Wolf Steel ltd., 24 napoleon rd., barrie, on, l4m 0G8 Canada / 103 miller drive, Crittenden, kentucky, uSA, 41030 Phone (705)721-1212 • fax (705)722-6031 • www.napoleonheatingandcooling.com • ask@napoleonheatingandcooling.com W415-1013 / A / 06.05.12...

-

Page 2: Table Des Matières

TABLE OF CONTENTS INSTALLATION OvErvIEw INTRODUCTION dimenSionS GenerAl inSTruCTionS GenerAl informATion 2.3.1 feATureS 2.3.2 HeATinG SPeCifiCATionS 2.3.3 eleCTriCAl SPeCifiCATionS 2.3.4 oPTionAl moduleS 2.3.5 APPliCAble STAndArdS 2.3.6 CAliforniA ProP65 rATinG PlATe informATion INSTALLATION pLANNINg loCATion And CleArAnCeS ouTSide CombuSTion Air UNCRATINg AND ASSEMBLY CrATed uniT ConTAinS reCommended STeP removAl of furnACe from bASe of Skid... -

Page 3: Installation Overview

1.0 INSTALLATION OvErvIEw THIS AppLIANCE AND ITS COMpONENTS ARE DESIgNED TO BE INSTALLED AND OpERATED AS A SYSTEM. ANY ALTERATION TO OR SUBSTITUTION FOR ITEMS IN THIS SYSTEM, UNLESS ALLOWED BY THESE INSTALLATION INSTRUCTIONS, WILL vOID THE OMNI LISTINg AND MAY vOID THE WAR- RANTY. -

Page 4: Introduction

2.0 INTrOduCTION • THIS AppLIANCE IS HOT WHEN OpERATED AND CAN CAUSE SEvERE BURNS IF CONTACTED. • do not operate appliance before reading and understanding operating instructions. failure to operate appliance according to operating instructions could cause fi re or injury. •... -

Page 5: Dimensions

dImENSIONS (365 mm) " (308 mm) " " (94 mm) (495 mm) " (643 mm) " (129 mm) " 24" (610 mm) " (740 mm) 5" (127 mm) " " (1173 mm) (1302 mm) " (768 mm) " " (510 mm) (329 mm) "... - Page 6 AIR FLOW CIRCULATION AND HEAT TRANSFER COMBUSTION AIR FLOW W415-1013 / A / 06.05.12...

-

Page 7: General Information

GENErAL INFOrmATION 2.3.1 FEATurES • maximum log length of 24" (610 mm) (Hmf150), • outside air for combustion and 30” (762 mm) (Hmf200) • Choice of glass door for radiant heat through front • long burn time - up to 12 hours (Hmf150), 18 of furnace, or solid door to provide more heating hours (Hmf200) through exchange surfaces... -

Page 8: Installation Planning

SUFFICIENTLY SHIELDED FROM pREvAILINg WINDS TO pREvENT FROM REvERSINg IN THE vENT SYSTEM. The napoleon Hmf150/200 may take outside combustion air directly into the appliance through a 4" (102 mm) inlet collar at the back of the unit. This inlet is to supply combustion air for the Hmf150/200 Wood furnace only. - Page 9 The 4" (102 mm) inlet can also draw combustion air from the room provided adequate make up air is avail- able. fresh air makeup for the oil furnaces must follow criteria set in installation standard CSA b139-09 "installation Code for oil burning equipment", and installed by a certified oil mechanic. fresh air makeup for gas fired furnaces must follow criteria set in installation standard CAn/CGA-b149.1 or CAn/CGA-b149.2.

-

Page 10: Uncrating And Assembly

4.0 uNCrATING ANd ASSEmBLy CrATEd uNIT CONTAINS • Primary Air Control kit • main / electrical Harness kit (1 pc.) • bricks (37 pcs. Hmf150, pcs. Hmf200) • baffles (2 pcs.) • Secondary Air Tubes (4 pcs. Hmf150, 5 pcs. Hmf200) •... -

Page 11: Removal Of Furnace From Base Of Skid

rEmOvAL OF FurNACE FrOm BASE OF SkId FURNACE BASE LOOSEN OFF LOCK NUT ADJUSTMENT FOOT SECURING BRACKET REMOVE LAG BOLT BASE SKID CAUTION HiGH CenTre of GrAviTy! uSe exTreme CAuTion To Avoid ToPPlinG of THe furnACe "CruSH HAzArd"! STEp #1: Push the furnace to one side until close to the weight tipping the skid. -

Page 12: Configuring Hmf150/200 As Left Or Right "Return Air" (Ra)

CONFIGurING HmF150/200 AS LEFT Or rIGHT "rETurN AIr” (rA) The Hmf150/200 can be installed upstream with the return air, (also supply air from pre existing furnace "add on" configuration), entering from the left or right hand sides of the furnace. The Hmf150/200 comes reTurn Air reTurn Air configured for left side rA. -

Page 13: Mounting Primary Air Control

mOuNTING PrImAry AIr CONTrOL IMpORTANT: This step must follow the plenum installation in Section 6.0. The plenum is not shown in diagrams below, for clarity purposes. location of the Primary Air Control in left and right rA. riGHT HAnd rA lefT HAnd rA 1. -

Page 14: Secondary Air Tubes

2. Assemble the control box as illustrated using the fasteners supplied. main air control box is secured with (3) screws into the rear panel and (1) through the inside flange of the main box and into the furnace top. 3. Check manual override operation of the shutter plate by sliding the primary damper lever up and down at the front of the Top damper bracket. - Page 15 STEp #2A (“TUBE LOCATOR BRACkET” STYLE INSTALLATION) ○ insert tab of stainless steel tube locator bracket into left most hole of the secondary air tube. ○ Secure the bracket to the manifold tube using 1/4” stainless steel hex bolt. STEp #2B (“HITCH pIN” STYLE INSTALLATION) ○...

-

Page 16: Door Handle Installation

dOOr HANdLE INSTALLATION DOOR LOCK SPRING HANDLE WASHER WASHER LATCH DOOR HANDLE NOTE: Position of door handle latch. DOOR SPACER FRONT vIEW DOOR HANDLE CONFIgURATION W415-1013 / A / 06.05.12... -

Page 17: Configuration Of Left And Right Return Air With Other Hybrid Modules

5.0 CONFIGurATION OF LEFT ANd rIGHT rETurN AIr wITH OTHEr HyBrId mOduLES Hybrid Hmf150/200 as a "Add on" to existing furnace (see Section 5.1). in this application the Hmfk-bmP50 blower module is not used. Hybrid Hmf150/200 as a Stand Alone Wood furnace, (see Section 5.2). -

Page 18: Hybrid Hmf150/200 As A "Add On" To Existing Furnace

HyBrId HmF150/200 AS A "Add ON" TO ExISTING FurNACE THE INSTALLATION OF THE FURNACE MUST BE DONE IN ACCORDANCE WITH RULES OF AU- THORITIES HAvINg jURISDICTION AND THE CAN / CSA B365-01 (R2006) STANDARD FOR SOLID FUEL BURNINg AppLIANCES AND EqUIpMENT. required ComPonenTS: •... - Page 19 • the equipment shall be installed in accordance with the instructions of the original furnace manufacturer and in a manner acceptable to the regulatory authority by qualified personnel. The operation of the original furnace must be verified for acceptable operation before and after installation of the "Add on".

- Page 20 INSTALLATION OF "ADD-ON" CONFIgURATION REqUIRES FIELD WIRINg BY A CERTIFIED ELEC- TRICIAN. ALL WIRINg TO CONFORM TO CSA 22.1. install wood limit switch: • locate and drill a 7/8" hole in the side of the plenum on the same side as the location of the Hmf150/200 main wire harness, as illustrated.

- Page 21 • Secure all flag connectors to switch terminals, route ground line to switch chassis, and check that jumper wire between line in and load has been installed. • Confirm limits on rotary dial as follows: HIgH LIMIT SET pOINT 250°F (121°C), CAUTION (NOT TO BE MOvED FROM THIS pOSITION!)

- Page 22 LOWER ELECTRICAL BOx - MAIN HARNESS HMF150/200 “B” HARNESS CONNECTOR LINES 12 & N TO ENGAGE COIL CONTROL WIRE FOR ON RELAY BLOWER CONTROL ON ORIGINAL RELAY BLOCK FURNACE FIELD SUPPLIED IN INSTALLATION “ADD ON ” MODULE KIT NOTE - instructions and specifications to be included in kit for: a) eCm motor in original furnace •...

-

Page 23: Hybrid Hmf150/200 As A "Stand Alone" Wood Furnace

HyBrId HmF150/200 AS A “STANd ALONE” wOOd FurNACE required ComPonenTS: • Hmf150/200 Hybrid furnace • Hmfk-bmP50 blower box module • Hmfk-Solid or Hmfk-GlASS door kit STEpS: Completely assemble Hmf150/200 in required left or right hand "rA" configuration as required. STEp #1 - #4 Follow Steps 1 to 4 from SECTION 5.1 - HYBRID HMF150/200 AS A "ADD ON"... - Page 24 STEp #8 ○ remove the access panel from the rear of the blower box module. ○ route the harness from the rear of the lower electrical box of the main electric harness to access the hole on the side of blower box. ACCeSS ○...

-

Page 25: Hybrid Hmf150/200 As A Combination "Wood/Oil" Furnace

HyBrId HmF150/200 AS A COmBINATION “wOOd/OIL” FurNACE THE INSTALLATION OF THE WOOD OIL COMBINATION FURNACE MUST BE DONE IN ACCORDANCE WITH THE RULES OF THE AUTHORITIES HAvINg jURISDICTION AND THE CAN / CSA B139-09 STANDARD FOR OIL BURNINg HEATINg AppLIANCES. required ComPonenTS: •... - Page 26 STEp #12A - For installation in HMF200 only. ○ The 5” flue pipe of the Hmfk-CmbCH-1 must be extended using kit number Hmfk-fe. detailed instruc- tions for mounting the flue extension are provided on leaflet supplied with the kit. once extension has been firmly secured, continue with Step #12b.

- Page 27 ○ locate flange gasket over bolts of oil furnace mounting flange, prior to placing bottom front cover up to mounting flange. ○ Align mounting bolts on flange align with clearance holes in bottom front panel when panel loosely fit in final position. ○...

- Page 28 STEp #15 NOTE Wire harness “C”, which runs from junction box and oil furnace burner, has been supplied at the length required for a right hand rA configuration. if installing oil furnace with a left hand rA configuration, the wires in the harness and the flex conduit will have to be shortened by approximately 12”...

- Page 29 STEp #16 THE MOUNTINg LOCATION AND MOUNTINg BRACkET FOR THE OIL LIMIT SWITCH ARE NOT THE SAME FOR THE HMF150 AND HMF200. STRICTLY ADHERE TO THE INSTRUCTION SET pERTAIN- INg TO THE MODEL BEINg INSTALLED. FAILINg TO DO SO COULD RESULT IN pOOR OpERATION, pROpERTY DAMAgE AND pERSONAL INjURY.

- Page 30 HMF200 oil limiT & oil limiT & furnACe furnACe mounTinG mounTinG flue flue brACkeT brACkeT oil limiT HArneSS oil limiT bloWer module HArneSS HArneSS bloWer module RIgHT HAND RA CONFIgURATION HArneSS LEFT HAND RA CONFIgURATION FIgURE B FIgURE A HiGH limiT SeT PoinT 250°f (121°C) fAn on/off...

- Page 31 NOTE Clearance holes in the 5" (127 mm) flue plate cover may not align perfectly with the original pilot holes in rear face of the rear panel. There is adequate clearance between the oil furnace flue and the flue exit hole in the rear panel to accommodate any misalignment between the two caused by standard fabrication tolerances.

- Page 32 STEp #18 ALL INSTALLATION AND MAINTENANCE MUST BE pERFORMED BY A qUALIFIED/LICENSED IN- STALLER. INCORRECT INSTALLATION, ADjUSTMENT, AND USE OF THE OIL BURNER COULD RE- SULT IN SEvERE pERSONAL INjURY, DEATH OR SUBSTANTIAL pROpERTY DAMAgE FROM FIRE, CARBON MONOxIDE pOISONINg, SOOT OR ExpLOSION. Connecting fuel to the oil module burner: ○...

-

Page 33: Hybrid Hmf150/200 As A Combination "Wood/Electric" Furnace

HyBrId HmF150/200 AS A COmBINATION “wOOd/ELECTrIC” FurNACE required ComPonenTS: • Hmf150/200 Hybrid furnace • Hmfk-bmP50 blower box module • Hmfk-ef15, -ef18, -ef20, -ef23, -ef25, -ef30, electric furnace module (HMFK-EF23, -EF25, -EF30 are available for the HMF200 only) • Hmfk-Solid or Hmfk-GlASS door kit STEpS #1 - #4 Follow Steps 1 to 4 from SECTION 5.1 - HYBRID HMF150/200 AS AN "ADD ON"... - Page 34 STEp #10 ○ lift open side of electric furnace module so as to allow mounting flange on bottom edge of electric fur- nace box to clear top edge of retaining bracket fastened to the lower edge of the rectangular window, the furnace side.

- Page 35 STEp #12 ○ See SeCTion 6.0 - Plenum And venTinG inSTAllATion. STEp #13 electrical furnace module Wiring: ○ feed one end of the harness through the open clearance hole in the front electrical knock out in the base of the blower module. ensure control box access facing the front of the unit with electrical heater coils to the bottom.

-

Page 36: Hybrid Hmf150/200 As A "Wood/Oil/Electric" Furnace

STEp #14 ○ See SeCTion 8.0 - oPerATinG inSTruCTionS. HyBrId HmF150/200 AS A “wOOd/OIL/ELECTrIC” FurNACE required ComPonenTS: • Hmf150/200 Hybrid furnace • Hmfk-bmP50 blower box module • Hmfk-ef15, -ef18, -ef20, -ef23, -ef25, -ef30, electric burner module (HMFK-EF23, -EF25, -EF30 are available for the HMF200 only) •... -

Page 37: Plenum And Venting Installation/Clearance To Combustible Materials

6.0 PLENum ANd vENTING INSTALLATION/ CLEArANCE TO COmBuSTIBLE mATErIALS ALL pLENUM DUCTINg AND vENTINg INSTALLATION MUST CONFORM WITH CAN/CSA B365-01, CSA B139-09, AND NFpA 211. ALWAYS CHECk LOCAL BUILDINg AND FIRE CODES , AND AUTHORI- TIES HAvINg jURISDICTION. ALL pLENUM, DUCTINg AND vENTINg MUST BE INSTALLED BY A qUALIFIED/LICENSED INSTALL- DO NOT USE MAkESHIFT COMpROMISES DURINg INSTALLATION. - Page 38 NOTE Connection of solid fuel and oil fired appliances to a common chimney, see Section 5.1.4 of CSA b139- 09 and Section 5.2.7 of CAn/CSA b365-01 for conditions allowing a single chimney for wood and oil. Common chimney must be approved for use with woodburning appliances (2100°f) (1149°C). STRICTLY ADHERE TO ALL IDENTIFIED INSTALLATION CLEARANCES.

-

Page 39: General Plenum And Ducting - Minimum Clearance To Combustibles

GENErAL PLENum ANd duCTING - mINImum CLEArANCE TO COmBuSTIBLES All plenum and ducting clearances must CLEARANCE TO COMBUSTIBLES 6” (152 mm) satisfy specification set forth in CAn/ 1” (25 mm) CSA-b365.01 and nfPA211. 40” NOTE: (1016 mm) CleArAnCe SeCTion 72” (1829 mm) CAN/CSA- CombuSTibleS... -

Page 40: Flue Configuration For "Add On" Furnace Configuration

FLuE CONFIGurATION FOr "Add ON" FurNACE CONFIGurATION ○ Separate chimneys are required when connecting the Hmf150/200 to a pre existing natural gas or pro- pane furnace. UNDER NO CONDITIONS MAY A SOLID FUEL BURNINg AppLIANCE SHARE A CHIMNEY THAT vENTS NATURAL gAS OR pROpANE ExHAUST. DO NOT USE MAkESHIFT COMpROMISES DURINg INSTALLATION. -

Page 41: Ember Stop

SAmPleS of AlloWAble Plenum/duCTinG ArrAnGemenTS ConTinued PROHIBITED ALLOWABLE “ADD ON” EXISTING WOOD FURNACE (down ow FURNACE “ADD ON” EXISTING or counter ow) WOOD FURNACE FURNACE HORIZONTAL EXISTING FURNACE DIVIDER “ADD ON” WOOD “ADD ON” FURNACE EXISTING WOOD FURNACE FURNACE “ADD ON” WOOD “ADD ON”... -

Page 42: Electrical Connections And Schematics

7.0 ELECTrICAL CONNECTIONS ANd SCHEmATICS ALL ELECTRICAL WIRINg AND CONNECTIONS MUST BE DONE BY A qUALIFIED ELECTRICIAN. THE ELECTRICAL INSTALLATION MUST SATISFY ALL RELEvANT ASpECTS OF CSA 22.1 AND IN pARTICULAR CAN/CSA-222.2 NO.0-M91, NO.3-M1988, NO. 23.1-M1986. ALL WIRINg BRINgINg 120v OR gREATER TO THE HMF150 AND ITS MODULES, SHALL BE AS SpECIFIED IN ELECTRICAL CODE BUT MUST HAvE WIRE INSULATION vALUE OF NO LESS THAN 90°C. -

Page 43: Electric Schematics - Wood "Add On" Configuration

ELECTrIC SCHEmATICS - wOOd "Add ON" CONFIGurATION NAPOLEON PRODUCTS HMF150/200 CONTROLS / CIRCUITRY DIAGRAM “ADD ON FIELD WIRING” 120 VAC SUPPLY WOOD LIMIT SUMMER SWITCH JUMPER 24 VAC WHITE BLACK BLACK / YELLOW “A” HARNESS NOT USED “C” HARNESS NOT USED... -

Page 44: Electric Schematics - Wood Only Furnace Configuration

ELECTrIC SCHEmATICS - wOOd ONLy FurNACE CONFIGurATION NAPOLEON PRODUCTS HMF150/200 CONTROLS / CIRCUITRY DIAGRAM “WOOD ONLY FIELD WIRING” 120 VAC SUPPLY WOOD LIMIT SUMMER SWITCH JUMPER 24 VAC WHITE BLACK BLACK / YELLOW “A” HARNESS NOT USED “C” HARNESS NOT USED... -

Page 45: Electric Schematics - Wood/Electric Furnace Configuration

ELECTrIC SCHEmATICS - wOOd/ELECTrIC FurNACE CONFIGurATION NAPOLEON PRODUCTS HMF150/200 CONTROLS / CIRCUITRY DIAGRAM “WOOD/ELECTRIC FIELD WIRING” 120 VAC SUPPLY WOOD LIMIT SUMMER SWITCH JUMPER 24 VAC WHITE BLACK BLACK / YELLOW “A” HARNESS NOT USED “C” HARNESS NOT USED C R G... -

Page 46: Electric Schematics - Wood/Oil Furnace Configuration

ELECTrIC SCHEmATICS - wOOd/OIL FurNACE CONFIGurATION NAPOLEON PRODUCTS HMF150/200 CONTROLS / CIRCUITRY DIAGRAM “WOOD/OIL FIELD WIRING” 120 VAC SUPPLY WOOD LIMIT SUMMER SWITCH JUMPER 24 VAC WHITE BLACK OIL LIMIT BLACK / YELLOW OIL BURNER C R G 9 10 11 12 CONNECTIONS FOR HMF150. -

Page 47: Electric Schematics - Wood/Oil/Electric Furnace Configuration

ELECTrIC SCHEmATICS - wOOd/OIL/ELECTrIC FurNACE CONFIGurATION NAPOLEON PRODUCTS HMF150/200 CONTROLS / CIRCUITRY DIAGRAM “WOOD/OIL/ELECTRIC FIELD WIRING” 120 VAC SUPPLY WOOD LIMIT SUMMER SWITCH JUMPER 24 VAC WHITE BLACK OIL LIMIT BLACK / YELLOW OIL BURNER C R G ELECTRIC FURNACE HARNESS... -

Page 48: General Operating Instructions

8.0 GENErAL OPErATING INSTruCTIONS CONTrOL SySTEm - wOOd FurNACE ○ Control of the woodburning section of the furnace is by adjustment of the primary air control located on the top rear right corner of the Hmf150/200. This control operates in two set positions - "full open" allowing maximum combustion air delivery to the fire box and "Closed", providing minimum primary air to the fire box to assist the development of secondary or gasifying burn in the top of the fire box (note that secondary combustion air enters through two inlets on the front of the furnace either side of the ash lip tray and is not... -

Page 49: Control System - Secondary Furnace "Add On", "Wood/Oil", "Wood/Electric", "Wood/Oil/Electric" Configurations

CONTrOL SySTEm - SECONdAry FurNACE "Add ON", "wOOd/OIL", "wOOd/ELECTrIC", "wOOd/OIL/ELECTrIC" CONFIGurATIONS ○ Control of the secondary heat source (either electric or oil) is done by a combination of a selector switch on the main furnace control panel and a second thermostat located beside and at the same height as the wood furnace thermostat. -

Page 50: Starting A Fire

STArTING A FIrE ALWAYS OpERATE THIS AppLIANCE WITH THE FIRE BOx DOOR CLOSED AND LATCHED ExCEpT DURINg START Up AND RE-FUELINg. ALWAYS WEAR gLOvES TO pREvENT INjURY. DO NOT LEAvE THE FIRE UNATTENDED WHEN THE DOOR IS UNLATCHED AS UNSTABLE WOOD COULD FALL OUT OF THE FIRE CHAMBER CREATINg A FIRE HAzARD TO YOUR HOME. -

Page 51: Draft Control

When a fire is burning, open the door slowly to avoid drawing smoke into the room. A properly installed napoleon® appliance should not smoke. if yours does, check the following: Has the chimney had time to... -

Page 52: Fuel Loading And Burn Cycle

FuEL LOAdING ANd BurN CyCLE BURN WOOD DIRECTLY ON THE FIREBRICkS. DO NOT USE ELEvATED gRATE OR OTHERWISE RAISE THE FIRE. DO NOT STORE WOOD WITHIN AppLIANCE INSTALLATION CLEARANCES OR WITHIN THE SpACE REqUIRED FOR RE-FUELINg AND ASH REMOvAL. The bricks will be nearly all white and the glass mostly clear. The whiteness of the bricks and the cleanness of the glass (if equipped) are good indicators of your operating efficiency. -

Page 53: Ash Removal Procedures

box or ash doors left open during fire). Although small flash fires are a part of developing a charcoal bed when starting the furnace up from a cold start they can create unsafe operating conditions, damage to the furnace and void all warranties. flash fires may only be used when starting the furnace from a cold start and the fuel stack should never occupy more than 1/3 of the firebox volume. -

Page 54: Maintenance

9.0 mAINTENANCE ruN-AwAy Or CHImNEy FIrE A CHIMNEY FIRE CAN pERMANENTLY DAMAgE YOUR CHIMNEY SYSTEM. THIS DAMAgE CAN ONLY BE REpAIRED BY REpLACINg THE DAMAgED COMpONENT pARTS. CHIMNEY FIRES ARE NOT COvERED BY THE LIFETIME LIMITED WARRANTY. run-away fires can be the result of four major factors: CAUSES: 1. -

Page 55: Firebricks And Baffles

FIrEBrICkS ANd BAFFLES inspect and replace all broken firebricks ad baffles. HMF150: HMF200: OpERATION OF THE AppLIANCE WITHOUT THE BAFFLES OR FIREBRICkS WILL DAMAgE THE Ap- pLIANCE, CHIMNEY AND THE SURROUNDINg ENCLOSURE. SELECTING wOOd THIS AppLIANCE IS DESIgNED TO BURN NATURAL WOOD ONLY. DO NOT BURN TREATED WOOD, COAL, CHARCOAL, COLOURED pApER, CARDBOARD, SOLvENTS OR gARBAgE. -

Page 56: Glass Replacement

GLASS rEPLACEmENT DO NOT SUBSTITUTE MATERIALS. gLASS MAY BE HOT, DO NOT TOUCH gLASS UNTIL COOLED. CARE MUST BE TAkEN WHEN REMOvINg AND DISpOSINg OF ANY BROkEN DOOR gLASS OR DAMAgED COMpONENTS. BE SURE TO vACUUM Up ANY BROkEN gLASS FROM INSIDE THE Ap- pLIANCE BEFORE OpERATION. -

Page 57: Creosote Formation And Removal

CrEOSOTE FOrmATION ANd rEmOvAL When wood is burned slowly, it produces tar and other organic vapors CREOSOTE IN EXCHANGER which combine with expelled moisture to form creosote. These vapors TUBES condense in the relatively cooler chimney flue of a slow burning fire and when ignited, make an extremely hot fire. -

Page 58: Chimney Maintenance

9.8.2 CHImNEy mAINTENANCE The most efficient method to sweep the chimney is using a hard brush. brush downwards so soot and creosote residues will come off the inner surface and fall at the bottom of the chimney where they can be removed easily. -

Page 59: Replacements

10.0 rEPLACEmENTS Contact your dealer or the factory for questions concerning prices and policies on replacement parts. normally all parts can be ordered through your Authorized dealer / distributor. FOR WARRANTY REpLACEMENT pARTS, A pHOTOCOpY OF THE ORIgINAL INvOICE WILL BE WARNING REqUIRED TO HONOUR THE CLAIM. -

Page 60: Trouble Shooting Guide

11.0 TrOuBLE SHOOTING GuIdE SYMPTOM PROBLEM TEST SOLUTION - Burn a piece of newspaper to establish a draft. Smoke enters the Cold air blockage in chimney. room during start-up. - If the flame is not getting enough air, first make sure the air control is Close the doors. -

Page 61: Warranty

After the fi rst year, NAPOLEON® will not be responsible for installation, labour or any other costs or expenses related to the reinstallation of a warranted part, and such expenses are not covered by this warranty. -

Page 62: Service History

13.0 SErvICE HISTOry 43.1 W415-1013 / A / 06.05.12... - Page 63 14.0 NOTES 44.1 W415-1013 / A / 06.05.12...