Table des Matières

Publicité

Liens rapides

MANUAL

XMT 425 CC/CV

ALUGUEL E VENDA DE MÁQUINAS DE

SOLDA E CORTE PLASMA

TODOS OS PROCESSOS DE SOLDAGEM

TRABALHAMOS EXCLUSIVAMENTE COM

AS MELHORES MÁQUINAS DO MUNDO

ASSESSORIA PARA PROCESSOS ESPECIAIS

TECNOLOGIA ATUALIZADA PARA

GARANTIR O MELHOR CUSTO BENEFÍCIO

AUMENTO DE PRODUTIVIDADE SOLDADOR-PEÇA

REDUÇÃO DE CUSTO COM ENERGIA

MIG MAG · TIG · ARCO SUBMERSO · MULTIPROCESSO · RETIFICADORAS CORTE PLASMA

INVERSORAS · ELETRODO · GERADORES DE ENERGIA · ROBÔS

www.aventa.com.br | contato@aventa.com.br

LOCAÇÃO E VENDA

MÁQUINAS DE SOLDA E CORTE

Publicité

Table des Matières

Dépannage

Sommaire des Matières pour Miller XMT 425 CC/CV Auto-Line

- Page 1 MANUAL XMT 425 CC/CV LOCAÇÃO E VENDA MÁQUINAS DE SOLDA E CORTE ALUGUEL E VENDA DE MÁQUINAS DE SOLDA E CORTE PLASMA TODOS OS PROCESSOS DE SOLDAGEM TRABALHAMOS EXCLUSIVAMENTE COM AS MELHORES MÁQUINAS DO MUNDO ASSESSORIA PARA PROCESSOS ESPECIAIS TECNOLOGIA ATUALIZADA PARA GARANTIR O MELHOR CUSTO BENEFÍCIO AUMENTO DE PRODUTIVIDADE SOLDADOR-PEÇA REDUÇÃO DE CUSTO COM ENERGIA...

- Page 2 OM-234 196E 2009−10 Processes Multiprocess Welding Description Arc Welding Power Source XMT 425 CC/CV ™ Auto-Line ™ File: MULTIPROCESS Visit our website at www.MillerWelds.com...

- Page 3 We know you don’t have time to do it any other way. That’s why when Niels Miller first started building arc welders in 1929, he made sure his products offered long-lasting value and superior quality.

-

Page 4: Table Des Matières

TABLE OF CONTENTS SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING ........1-1. -

Page 6: Section 1 − Safety Precautions - Read Before Using

SECTION 1 − SAFETY PRECAUTIONS - READ BEFORE USING som _2009−08 Protect yourself and others from injury — read and follow these precautions. 1-1. Symbol Usage DANGER! − Indicates a hazardous situation which, if Indicates special instructions. not avoided, will result in death or serious injury. The possible hazards are shown in the adjoining symbols or explained in the text. - Page 7 D Remove stick electrode from holder or cut off welding wire at FUMES AND GASES can be hazardous. contact tip when not in use. D Wear oil-free protective garments such as leather gloves, heavy Welding produces fumes and gases. Breathing shirt, cuffless trousers, high shoes, and a cap.

-

Page 8: Additional Symbols For Installation, Operation, And Maintenance

1-3. Additional Symbols For Installation, Operation, And Maintenance FIRE OR EXPLOSION hazard. MOVING PARTS can injure. D Do not install or place unit on, over, or near D Keep away from moving parts such as fans. combustible surfaces. D Keep all doors, panels, covers, and guards D Do not install unit near flammables. -

Page 9: California Proposition 65 Warnings

1-4. California Proposition 65 Warnings For Gasoline Engines: Welding or cutting equipment produces fumes or gases which contain chemicals known to the State of California to Engine exhaust contains chemicals known to the State of cause birth defects and, in some cases, cancer. (California California to cause cancer, birth defects, or other reproduc- Health &... -

Page 10: Section 2 − Consignes De Sécurité − Lire Avant Utilisation

SECTION 2 − CONSIGNES DE SÉCURITÉ − LIRE AVANT UTILISATION fre_som_2009−08 Se protéger et protéger les autres contre le risque de blessure — lire et respecter ces consignes. 2-1. Symboles utilisés DANGER! − Indique une situation dangereuse qui si on Indique des instructions spécifiques. - Page 11 Il reste une TENSION DC NON NÉGLIGEABLE dans D Porter des vêtements confectionnés avec des matières résistan- tes et ignifuges (cuir, coton lourd ou laine) et des bottes de les sources de soudage onduleur UNE FOIS protection. l’alimentation coupée. LE SOUDAGE peut provoquer un D Arrêter les convertisseurs, débrancher le courant électrique et incendie ou une explosion.

-

Page 12: Dangers Supplémentaires En Relation Avec L'installation, Le Fonctionnement Et La Maintenance

ACCUMULATIONS LES BOUTEILLES peuvent exploser risquent de provoquer des blessures si elles sont endommagées. ou même la mort. Des bouteilles de gaz protecteur contiennent du gaz sous haute pression. Si une bouteille est endom- D Fermer l’alimentation du gaz protecteur en cas magée, elle peut exploser. -

Page 13: Proposition Californienne 65 Avertissements

Les PIÈCES MOBILES peuvent RAYONNEMENT HAUTE causer des blessures. FRÉQUENCE (H.F.) risque provoquer des interférences. D Ne pas s’approcher des organes mobiles. D Ne pas s’approcher des points de coincement D Le rayonnement haute fréquence (H.F.) peut tels que des rouleaux de commande. provoquer des interférences avec les équi- pements de radio−navigation et de com- munication, les services de sécurité... -

Page 14: Principales Normes De Sécurité

2-5. Principales normes de sécurité Safety in Welding, Cutting, and Allied Processes, ANSI Standard Z49.1, 25 West 43rd Street, New York, NY 10036 (téléphone : 212-642-4900, de Global Engineering Documents (téléphone : 1-877-413-5184, site site Internet : www.ansi.org). Internet : www.global.ihs.com). Standard for Fire Prevention During Welding, Cutting, and Other Hot Safe Practices for the Preparation of Containers and Piping for Welding Work, NFPA Standard 51B, de National Fire Protection Association,... -

Page 15: Section 3 − Introduction

SECTION 3 − INTRODUCTION 3-1. Serial Number And Rating Label Location The serial number and rating information for this product is located on the rear panel. Use rating label to determine input power requirements and/or rated output. For future reference, write serial number in space provided on back cover of this manual. 3-2. -

Page 16: Duty Cycle And Overheating

3-4. Duty Cycle And Overheating Duty Cycle is percentage of 10 min- utes that unit can weld at rated load without overheating. If unit overheats, output stops, a Help message is displayed and cooling fan runs. Wait fifteen min- utes for unit to cool. Reduce amper- age or voltage, or duty cycle before welding. -

Page 17: Section 4 − Installation

SECTION 4 − INSTALLATION 4-1. Dimensions And Weight Hole Layout Dimensions 24 in. (610 mm) 11-3/4 in. (298 mm) 17 in. 1-11/16 in. (42 mm) (432 mm) 15-3/4 in. (400 mm) 19-3/32 in. (485 mm) 12-1/2 in. 8-11/16 in. (221 mm) (318 mm) 1-17/32 in. -

Page 18: Connecting 3-Phase Input Power

4-3. Connecting 3-Phase Input Power Installation must meet all National and Local Codes − have only quali- fied persons make this installation. Disconnect and lockout/tagout in- put power before connecting input conductors from unit. Always connect green or green/ yellow conductor supply grounding terminal first, and never... -

Page 19: Electrical Service Guide

4-4. Electrical Service Guide NOTICE − INCORRECT INPUT POWER can damage this welding power source. Phase to ground voltage shall not exceed +10% of rated input voltage. NOTICE − Actual input voltage should not be 10% less than minimum and/or 10% more than maximum input voltages listed in table. If actual input voltage is outside this range, output may not be be available. -

Page 20: Weld Output Terminals And Selecting Cable Sizes

**Weld cable size (AWG) is based on either a 4 volts or less drop or a current density of at least 300 circular mils per ampere. ( ) = mm for metric use ***For distances longer than those shown in this guide, call a factory applications rep. at 920-735-4505 (Miller) or 1-800-332-3281 (Hobart) Ref. S-0007-G 2009−08 OM-234 196 Page 15... -

Page 21: Remote 14 Receptacle Information

4-6. Remote 14 Receptacle Information Socket* Socket Information 24 volts AC. Protected by supplementary protect- 24 VOLTS AC or CB2. Contact closure to A completes 24 volts AC contactor control circuit. 115 volts AC. Protected by supplementary pro- C L N 115 VOLTS AC tector CB1. -

Page 22: Optional Gas Valve Operation And Shielding Gas Connection

‘ 4-8. Optional Gas Valve Operation And Shielding Gas Connection Obtain gas cylinder and chain to running gear, wall, or other station- ary support so cylinder cannot fall and break off valve. Cylinder Regulator/Flowmeter Install so face is vertical. Gas Hose Connection GAS IN Fitting has 5/8-18... -

Page 23: Section 5 − Operation

SECTION 5 − OPERATION 5-1. Front Panel Controls Power Switch sults, place Arc Control in the maximum posi- When set towards maximum, short-circuit tion. amperage is increased at low arc voltage to The fan motor is thermostatically assist with arc starts as well as reduce stick- Remote 14 Receptacle controlled and only runs when cooling is ing while welding. -

Page 24: Meter Functions

5-2. Meter Functions The meters display the actual weld output values for approximately three seconds after the arc is broken. Mode Meter Reading At Idle Meter Reading While Welding Scratch 71.7 10.3 Start TIG Actual Volts (OCV) Preset Amps Actual Volts Actual Amps 14.1 10.3... -

Page 25: Lift-Arc Tig Procedure

5-4. Lift-Arc TIG Procedure With Process Switch in the Lift-Arc TIG position, start an arc as follows: TIG Electrode Workpiece Touch tungsten electrode to work- piece at weld start point, hold electrode to workpiece for 1-2 seconds, and slowly lift electrode. An arc will form when electrode is lifted. -

Page 26: Section 6 − Maintenance & Troubleshooting

SECTION 6 − MAINTENANCE & TROUBLESHOOTING 6-1. Routine Maintenance Disconnect power Maintain more often before maintaining. during severe conditions. 3 Months Repair Or Replace Replace Cracked Replace Damaged Or Torch Body Cracked Unreadable Cables Labels Repair Or Replace Cracked Cables And Cords Clean Tighten Weld... -

Page 27: Voltmeter/Ammeter Help Displays

6-3. Voltmeter/Ammeter Help Displays All directions are in reference to the front of the unit. All circuitry referred to is located inside the unit. Help 1 Display HE.L P−1 Indicates a malfunction in the prima- ry power circuit. If this display is shown, contact a Factory Authorized Service Agent. -

Page 28: Troubleshooting

6-4. Troubleshooting Trouble Remedy No weld output; unit completely inop- Place line disconnect switch in On position (see Section 4-3). erative. Check and replace line fuse(s), if necessary, or reset circuit breaker (see Section 4-3). Check for proper input power connections (see Section 4-3). No weld output;... -

Page 29: Section 7 − Electrical Diagram

SECTION 7 − ELECTRICAL DIAGRAM Figure 7-1. Circuit Diagram OM-234 196 Page 24... - Page 30 246 067-A OM-234 196 Page 25...

-

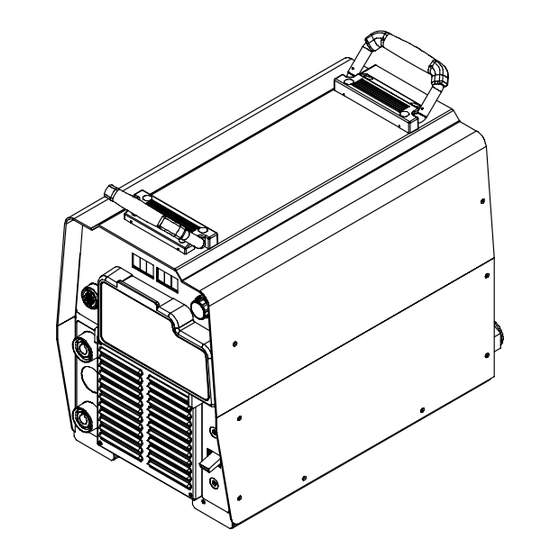

Page 31: Section 8 − Parts List

SECTION 8 − PARTS LIST Ref. 803 690-H Figure 8-1. Parts Assembly OM-234 196 Page 26... - Page 32 Item Dia. Part Mkgs. Description Quantity Figure 8-1. Parts Assembly ....216 034 Wrapper (Includes Insulators and Safety Labels) ....

- Page 33 Item Dia. Part Mkgs. Description Quantity Figure 8-1. Parts Assembly (Continued) ......Nameplate, Rear (Order by Model and Serial Number) .

- Page 34 Item Dia. Part Mkgs. Description Quantity Figure 8-1. Parts Assembly (Continued) ....♦♦218 183 Rcpt Assy, Tw Lk Insul Fem (Tweco Type) (Fac-op) (Includes) ..

- Page 35 Notes Start Your Professional Over 80,000 trained 400 Trade Square East, Troy, Ohio 45373 Welding Career Now! since 1930! 1-800-332-9448 www.welding.org...

- Page 36 Effective January 1, 2009 (Equipment with a serial number preface of LK or newer) This limited warranty supersedes all previous Miller warranties and is exclusive with no other Warranty Questions? guarantees or warranties expressed or implied. LIMITED WARRANTY − Subject to the terms and conditions...

-

Page 37: For Service

Contact the Delivering Carrier to: File a claim for loss or damage during shipment. For assistance in filing or settling claims, contact your distributor and/or equipment manufacturer’s Transportation Department. © ORIGINAL INSTRUCTIONS − PRINTED IN USA 2009 Miller Electric Mfg. Co. 2009−01...