Sommaire des Matières pour Agilent Technologies 929-0200

- Page 1 MicroVac Controller Models 929-0200 929-0201 Manuale di Istruzioni Bedienungshandbuch Notice de Mode D’Emploi User Manual 87-900-089-01 (G) 05/2011...

-

Page 2: Safety Notices

Use, duplication or disclosure of Software is subject to The material contained in this Agilent Technologies’ standard © Agilent Technologies, Inc. 2011 document is provided “as is,” and is commercial license terms, and non- subject to being changed, without... - Page 3 MicroVac Controller MicroVac Controller MicroVac Controller User Manual / 87-900-089-01 (G) 3/72...

- Page 4 MicroVac Controller 4/72 MicroVac Controller User Manual / 87-900-089-01 (G)

-

Page 5: Table Des Matières

Contents Contents Istruzioni per l’uso 9 Informazioni Generali 10 Immagazzinamento 11 Preparazione per l'installazione 11 Installazione 12 Uso 13 Procedure di uso 17 Manutenzione 18 Smaltimento 18 Gebrauchsanleitung 19 Allgemeines 20 Lagerung 21 Vor der Installation 21 Installation 22 Gebrauch 23 ... - Page 6 Contents Mode d’emploi 29 Indications Generales 30 Preparation pour l'installation 31 Installation 32 Utilisation 33 Procedures d'utilisation 37 Entretien 38 Mise au rebut 38 Instructions for Use 39 General Information 40 Storage 41 Preparation for Installation 41 Installation 42 Use 43 Use Procedure 47 ...

- Page 7 Contents Use 62 Replacement 64 Accessories and Spares Parts 65 MicroVac Controller User Manual / 87-900-089-01 (G) 7/72...

- Page 8 Contents 8/72 MicroVac Controller User Manual / 87-900-089-01 (G)

-

Page 9: Istruzioni Per L'uso

MicroVac Controller User Manual Istruzioni per l’uso Informazioni Generali 10 Immagazzinamento Preparazione per l'installazione 11 Installazione Comandi, Indicatori e Connettori del Controller 13 Installazione Scala Graduata in Pascal o in Millibar Fornita come Accessorio Procedure di uso 17 Accensione del Controller Avvio della Pompa Arresto della Pompa Manutenzione... -

Page 10: Informazioni Generali

Istruzioni per l’uso Informazioni Generali Informazioni Generali Questa apparecchiatura è destinata ad uso professionale. L'utilizzatore deve leggere attentamente il presente manuale di istruzioni ed ogni altra informazione addizionale fornita dalla Agilent prima dell'utilizzo dell'apparecchiatura. La Agilent si ritiene sollevata da eventuali responsabilità dovute all'inosservanza totale o parziale delle istruzioni, ad uso improprio da parte di personale non addestrato, ad interventi non autorizzati o ad uso contrario alle normative nazionali specifiche. -

Page 11: Immagazzinamento

Istruzioni per l’uso Immagazzinamento Immagazzinamento Durante il trasporto e l'immagazzinamento dei MicroVac devono essere soddisfatte le seguenti condizioni ambientali: temperatura: da -20 °C a +70 °C umidità relativa: 0 – 95 % (non condensante) Preparazione per l'installazione Il controller viene fornito in un imballo protettivo speciale; se si presentano segni di danni, che potrebbero essersi verificati durante il trasporto, contattare l'ufficio vendite locale. -

Page 12: Installazione

Ogni controller giunge dalla Agilent predisposto per una certa tensione di alimentazione: il modello 929-0201 KINGS type High voltage connector (220 Vac, 50/60 Hz) il modello 929-0200 KINGS type High voltage connector (120 Vac, 50/60 Hz) Installazione AVVERTENZA! Il controller è fornito di un cavo di alimentazione a tre fili con una spina di tipo approvato a livello internazionale. -

Page 13: Uso

Istruzioni per l’uso In questo paragrafo sono riportate le principali procedure operative. Per ulteriori dettagli e per procedure che coinvolgono collegamenti o particolari opzionali, fare riferimento al paragrafo "Use" della sezione "Technical Information". Prima di usare il controller effettuare tutti i collegamenti elettrici e pneumatici e fare riferimento al manuale della pompa collegata. - Page 14 Istruzioni per l’uso Figura 2 Pannello frontale del Controller Interruttore ON/OFF principale H. V. LED Connettore di uscita segnale proporzionale alla corrente 10 V= 1 mA log Scala in corrente (mA) Led High Load, lampeggia quando la corrente assorbita dalla pompa raggiunge il valore di 1 mA Scala di pressione per pompa Mini Scala di pressione per pompa da 2 l/s...

- Page 15 Istruzioni per l’uso Figura 3 Pannello posteriore dei Controller Modulo di ingresso dell’alimentazione per il Controller. Comprende il fusibile di protezione, il cambia-tensione, la presa di alimentazione di potenza ed il filtro EMC (non compreso nel blocco presa/cambia-tensione). Connettore di uscita alta tensione per alimentazione pompa (tipo KINGS). Connettore per abilitazione alta tensione in uscita (H.V.

-

Page 16: Installazione Scala Graduata In Pascal O In Millibar Fornita Come Accessorio

Istruzioni per l’uso Installazione Scala Graduata in Pascal o in Installazione Scala Graduata in Pascal o in Millibar Fornita come Accessorio Millibar Fornita come Accessorio I controller della linea MicroVac vengono forniti con la scala della I controller della linea MicroVac vengono forniti con la scala della pressione espressa in Torr (Torricelli);... -

Page 17: Procedure Di Uso

Istruzioni per l’uso Procedure di uso Procedure di uso Accensione del Controller Per accendere il controller portare l’interruttore principale in posizione ON dopo aver inserito il cavo di alimentazione nella presa di rete. Avvio della Pompa La pompa si avvia solo se il controller è acceso e i due interlock (H.V. Cable e Remote ON/OFF) sono cortocircuitati. -

Page 18: Manutenzione

Istruzioni per l’uso Manutenzione Manutenzione I controller della serie MicroVac non richiedono alcuna manutenzione. Qualsiasi intervento deve essere eseguito da personale autorizzato. In caso di guasto è possibile usufruire del servizio di riparazione Agilent o del "Agilent advance exchange service", che permette di ottenere un controller rigenerato in sostituzione di quello guasto. -

Page 19: Gebrauchsanleitung

MicroVac Controller User Manual Gebrauchsanleitung Allgemeines Lagerung Vor der Installation Installation Gebrauch Steuerungen, Anzeigen und Anschlüsse des Controllers 23 Installation der als Zubehör gelieferten Skala in Pascal oder Millibar 26 Bedienung Einschalten des Controllers 27 Pumpenstart 27 Pumpenstopp 27 Wartung Entsorgung Übersetzung der Originalanleitungen 19/72... -

Page 20: Allgemeines

Gebrauchsanleitung Allgemeines Allgemeines Dieser Apparat ist für Fachbetriebe bestimmt. Vor Gebrauch sollte der Benutzer dieses Handbuch sowie alle weiteren mitgelieferten Zusatzdokumentationen genau lesen. Bei - auch nur teilweiser - Nichtbeachtung der enthaltenen Hinweise, unsachgemäßem Gebrauch durch ungeschultes Personal, nicht autorisierten Eingriffen und Mißachtung der einheimischen, hier zur Geltung kommenden Bestimmungen übernimmt die Firma Agilent keinerlei Haftung. -

Page 21: Lagerung

Gebrauchsanleitung Lagerung Lagerung Beim Transport und bei der Lagerung der Controller müssen folgende klimatische Verhältnisse eingehalten werden: Temperatur: von -20 °C bis +70 °C Relative Luftfeuchtigkeit: 0 – 95 % (nicht kondensierend) Vor der Installation Der Controller wird mit einer speziellen Schutzverpackung geliefert. Eventuelle Transportschäden müssen der zuständigen örtlichen Verkaufsstelle gemeldet werden. -

Page 22: Installation

Alle Agilent-Controller sind für eine bestimmte Anschlußspannung ausgelegt: das Modell 929-0201 KINGS type High voltage connector (220 V, 50/60 Hz) das Modell 929-0200 KINGS type High voltage connector (120 V, 50/60 Hz) Installation Der Controller wird mit einem 3-adrigen Netzkabel geliefert, das mit einem WARNUNG! den internationalen Normen entsprechenden Stecker ausgerüstet ist. -

Page 23: Gebrauch

Gebrauchsanleitung Gebrauch Gebrauch In diesem Kapitel sind die wichtigsten Betriebsvorgänge aufgeführt. Für weitere Hinweise bezüglich Anschlüsse und Montage des bestellbaren Zubehörs siehe Kapitel "Use" im Anhang zu "Technical Information". Vor Benutzung des Controllers sämtliche elektrischen und pneumatischen Anschlüsse ausführen, und die Betriebsanleitung der angeschlossenen Pumpe durchlesen. - Page 24 Gebrauchsanleitung Gebrauch Abbildung 2 Bedienfeld der Controller Hauptschalter ON/OFF Hochspannungs- LED Ausgangsstecker für Strom-proportionales Signal 10 V= 1 mA log Stromskala (mA) Hochlast-LED, blinkt, wenn der von der Pumpe aufgenommene Strom 1 mA erreicht Druckskala für Mini-Pumpe Druckskala für Pumpe mit 2 l/s Hochspannungs-LED Netz- LED 24/72...

- Page 25 Gebrauchsanleitung Gebrauch Abbildung 3 Rücktafel der Controller Eingangsmodul der Controller-Stromversorgung mit Sicherung, Spannungswahlschalter, Leistungsstecker und EMC-Filter (nicht im Block Stecker/Spannungswahlschalter eingeschlossen). Hochspannungs-Ausgangsstecker zur Pumpen versorgung (Typ KINGS). Stecker zur Aktivierung der Ausgangshochspannung (H.V. Cable Interlock). Eingangs-/Ausgangsstecker für Signale für Zubehör. MicroVac Controller User Manual / 87-900-089-01 (G) 25/72...

-

Page 26: Installation Der Als Zubehör Gelieferten Skala In Pascal Oder Millibar

Gebrauchsanleitung Gebrauch Installation der als Zubehör gelieferten Skala in Installation der als Zubehör gelieferten Skala in Pascal oder Millibar Pascal oder Millibar Die Controller der MicroVac Serie werden mit Druckskala in Torr Die Controller der MicroVac Serie werden mit Druckskala in Torr (Torricelli) geliefert. -

Page 27: Bedienung

Gebrauchsanleitung Bedienung Bedienung Einschalten des Controllers Zum Einschalten des Controllers genügt es, das Netzkabel an die Steckdose anzuschließen. Pumpenstart D Die Pumpe startet nur, wenn der Controller eingeschaltet ist und die beiden Verriegelungen (Hochspannungskabel und Remote ON/OFF) kurzgeschlossen sind. Weiteres findet sich im Abschnitt “Technical Information”. -

Page 28: Wartung

Gebrauchsanleitung Wartung Wartung Die Controller der MicroVac Serie brauchen keinerlei Wartung. Alle Eingriffe dürfen nur von autorisiertem Personal vorgenommen werden. Bei Defekten kann der Reparatur Service von Agilent oder der "Agilent Advance Exchange Service" in Anspruch genommen werden, der den defekten Controller durch ein Austauschgerät ersetzt. WARNUNG! Vor jedem Eingriff am Controller muß... - Page 29 MicroVac Controller User Manual Mode d’emploi Indications Generales 30 Emmagasinage Preparation pour l'installation 31 Installation Utilisation Commandes, Indicateurs et Connecteurs du Contrôleur 33 Installation échelle graduée en Pascal ou en Millibar livrée comme accessoire Procedures d'utilisation Mise sous tension du Contrôleur 37 Mise en marche de la Pompe Arrêt de la Pompe 37 Entretien...

-

Page 30: Mode D'emploi Indications Generales

Mode d’emploi Indications Generales Indications Generales Cet appareillage a été conçu en vue d'une utilisation professionnelle. L'utilisateur doit lire attentivement cette notice d'instructions ainsi que toute autre indication supplémentaire fournie par Agilent, avant l'utilisation de l'appareil. Agilent décline toute responsabilité quant à: non-respect total ou partiel des instructions pour l’utilisation, mauvais usage par du personnel non formé, opérations non autorisées usage contraire aux réglementations nationales... -

Page 31: Preparation Pour L'installation

Mode d’emploi Preparation pour l'installation Emmagasinage Pendant le transport et l'emmagasinage des Micro Vaccontrôleurs, il faudra veiller à respecter les conditions environnementales suivantes: Température: de - 20 °C à + 70 °C Humidité relative: 0 – 95 % (non condensante). Preparation pour l'installation Le contrôleur est fourni dans un emballage de protection spécial;... -

Page 32: Installation

Chaque contrôleur est fourni par Agilent prééquipé pour une certaine tension d'alimentation: modèle 929-0201 KINGS type High voltage connector (220 Vca, 50/60 Hz) modèle 929-0200 KINGS type High voltage connector (120 Vca, 50/60 Hz) Installation AVERTISSEMENT! Le contrôleur est doté d'un câble d'alimentation à trois fils avec une fiche du type approuvé... -

Page 33: Utilisation

Mode d’emploi Utilisation Utilisation Ce paragraphe décrit les principales procédures de fonctionnement. Pour tout autre complément d’information et pour les procédures concernant des connexions ou des éléments en option, se reporter au paragraphe "Use" de la section "Technical Information". Avant d'utiliser le contrôleur, effectuer toutes les connexions électriques et pneumatiques et se référer à... - Page 34 Mode d’emploi Utilisation Figure 2 Tableau avant du Contrôleur Interrupteur ON/OFF principal LED H. T. Connecteur de sorite signal proportionnel au courant 10 V= 1 mA log Echelle de courant (mA) Led High Load (Charge élevée), il clignote quand le courant consommé par la pompe atteint la valeur de 1 mA Echelle de pression pour pompe Mini Echelle de pression pour pompe de 2 l/s...

- Page 35 Mode d’emploi Utilisation Figure 3 Tableau arrière des Contrôleurs Module d’entrée de l’alimentation du Contrôleur. Il est doté du fusible de protection, du dispositif de changement de tension, de la prise d’alimentation en puissance et du filtre EMC (qui n’est pas compris dans le bloc prise/dispositif de changement de tension).

-

Page 36: Installation Échelle Graduée En Pascal Ou En Millibar Livrée Comme Accessoire

Mode d’emploi Utilisation Installation échelle graduée en Pascal ou en Installation échelle graduée en Pascal ou en Millibar livrée comme accessoire Millibar livrée comme accessoire Les contrôleurs de la gamme MicroVac sont livrés avec l’échelle de la Les contrôleurs de la gamme MicroVac sont livrés avec l’échelle de la pression exprimée en Torr (Torricelli);... -

Page 37: Procedures D'utilisation

Mode d’emploi Procedures d'utilisation Procedures d'utilisation Mise sous tension du Contrôleur Pour mettre le contrôleur sous tension, il suffit de mettre l’interrupteur principal sur ON après avoir branché le câble d'alimentation sur la prise du réseau. Mise en marche de la Pompe La pompe se met en marche uniquement si le contrôleur est sous tension et si les deux dispositifs d’interverrouillage (H.V. -

Page 38: Entretien

Mode d’emploi Entretien Entretien Les contrôleurs de la série MicroVac ne requièrent aucun entretien. Toute intervention doit être effectuée par du personnel autorisé. En cas de panne, il est possible de faire appel au service de réparation Agilent ou au "Agilent advance exchange service", qui permet d’obtenir un contrôler régénéré... -

Page 39: Instructions For Use

MicroVac Controller User Manual Instructions for Use General Information Storage Preparation for Installation 41 Installation 42 Controller Controls, Indicators and Connectors 43 Pascal or Millibar Graduated Scale Installation (Supplied as a Fitting) 46 Use Procedure Controller Start-up 47 Starting the Pump 47 Pump Shutdown Maintenance Disposal... -

Page 40: General Information

Instructions for Use General Information General Information This equipment is destined for use by professionals. The user should read this instruction manual and any other additional information supplied by Agilent before operating the equipment. Agilent will not be held responsible for any events occurring due to non-compliance, even partial, with these instructions, improper use by untrained persons, non-authorised interference with the equipment or any action contrary to that provided for by specific national standards. -

Page 41: Storage

Instructions for Use Storage torage When transporting and storing the MicroVacs, the following environmental requirements should be satisfied: temperature: from -20 °C to + 70 °C relative humidity: 0 – 95 % (without condensation) Preparation for Installation The controller is supplied in a special protective packing. If this shows signs of damage which may have occurred during transport, contact your local sales office. -

Page 42: Installation

Installation Each controller is factory set for a specific power supply: model 929-0201 KINGS type High voltage connector (220 Vac, 50/60 Hz) model 929-0200 KINGS type High voltage connector (120 Vac, 50/60 Hz) Installation WARNING! The controller is equipped with a 3-wire power cord and plug (internationally approved) for user's safety. -

Page 43: Use

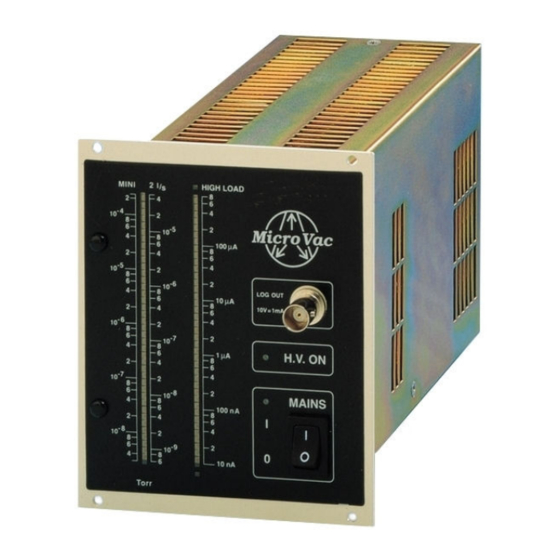

Instructions for Use This paragraph describes the fundamental operating procedures. Detailed information and operating procedures that involve optional connections or options are supplied in the paragraph "USE" of the section "Technical Information". Make all vacuum manifold and electrical connections and refer to the pump instruction manual prior to operating the controller. - Page 44 Instructions for Use Figure 2 Controller Front Panel ON/OFF main switch H. V. LED Output signal proportional to 10 V = 1 mA log current connector Scale expressed in current (mA) High Load Led; it blinks on when the current absorbed by the pump reaches a value equal to 1 mA Pressure scale for Mini pump Pressure scale for 2 l/s pump...

- Page 45 Instructions for Use Figure 3 Controller Rear Panel Input module for the controller power supply. It includes the protection fuse, the voltage changer, the power supply plug, and the EMC filter (not included into the plug/voltage switch assembly). High voltage output connector for the pump (KINGS type) power supply. Connector for the output high voltage activation (H.V.

-

Page 46: Pascal Or Millibar Graduated Scale Installation (Supplied As A Fitting)

Instructions for Use Pascal or Millibar Graduated Scale Installation Pascal or Millibar Graduated Scale Installation (Supplied as a Fitting) (Supplied as a Fitting) The MicroVac series controllers are supplied with the pressure scale The MicroVac series controllers are supplied with the pressure scale expressed in Torr (Torricelli);... -

Page 47: Use Procedure

Instructions for Use Use Procedure Use Procedure Controller Start-up To start-up the controller, turn the main switch to ON, after plugging the power cable into a suitable power source. Starting the Pump The pump starts only when the controller is turned on and the two interlocks (H.V. -

Page 48: Maintenance

Instructions for Use Maintenance Maintenance The MicroVac series controllers do not require any maintenance interventions. Any intervention must be performed by authorised personnel only. When a fault has occurred it is possible to use the Agilent repair service or the “Agilent advance exchange service”, that allows to obtain a regenerated controller replacing the faulty one. -

Page 49: Technical Information

MicroVac Controller User Manual Technical Information MicroVac Controller Description 50 Controller Specifications Controller Outline 55 Interconnections 56 Fuse Holder and Voltage Changer Assembly 57 Input/Output Interconnections Input Signals Output Signals Pump Connection 60 Interlock 60 General Pressure Determination Power Failure 63 Remote Control Mode Operation 63 Replacement General... -

Page 50: Microvac Controller Description

The MicroVac controller is available in two versions, which differ in the factory-set input voltage and in the high voltage output connector type. Model 929-0200 KINGS type High voltage connector (120 Vac, 50/60 Hz) Model 929-0201 KINGS type High voltage connector (220 Vac, 50/60 Hz) A voltage change over allows to select different operating voltages. - Page 51 Technical Information MicroVac Controller Description Figure 5 MicroVac Controller MicroVac Controller User Manual / 87-900-089-01 (G) 51/72...

-

Page 52: Controller Specifications

Safety EN 61010 - 1 Installation category Pollution degree Output Connector: - High voltage KINGS type: P/N 10664-I for Model 929-0200 and 929-0201 - Accessory J 101 input/output signal (9-pin “D” type socket) Cable Mains, 3 meters long Weight: 1.7 Kg (4 lbs) - Page 53 Technical Information MicroVac Controller Description CURRENT (A) Figure 6 Pump current/voltage diagram Figure 7 Voltage/current diagram on front connector MicroVac Controller User Manual / 87-900-089-01 (G) 53/72...

- Page 54 Technical Information MicroVac Controller Description PRESSURE (TORR) Figure 8 Pressure/voltage diagram on front connector for 2 l/s pump and Minipump 54/72 MicroVac Controller User Manual / 87-900-089-01 (G)

-

Page 55: Controller Outline

Technical Information Controller Outline Controller Outline The outline dimensions of the MicroVac controllers are shown in the following figures. Figure 9 Controller outline MicroVac Controller User Manual / 87-900-089-01 (G) 55/72... -

Page 56: Interconnections

Technical Information Interconnections Interconnections The following figure shows the Controller interconnections. Figure 10 Controller interconnections 56/72 MicroVac Controller User Manual / 87-900-089-01 (G) -

Page 57: Fuse Holder And Voltage Changer Assembly

Technical Information Fuse Holder and Voltage Changer Assembly Fuse Hold er and Voltage Changer Assembly If a change in line voltage operation is desired, proceed as follows: Unplug the power cord from the controller rear panel socket. On the power entry module (rear panel), check back door for voltage selector set. -

Page 58: Input/Output Interconnections

Technical Information Fuse Holder and Voltage Changer Assembly Figure 12 Voltage Changer Check voltage selector window for correct set and connect the power cord. Input/Output Interconnections All input/output signals are accessible at J001 accessory connector. With the provided P001 mating connector make the connections with AWG 24 (0.24 mm ) - or smaller wire - to the pins indicated in following figure, to obtain the desired capability. -

Page 59: Output Signals

Technical Information Fuse Holder and Voltage Changer Assembly utput Signals The front panel REC.OUT connector is a duplicate of this signal on a BNC connector. Tab. 2 DESCRIPTION Current recorder output (pin 2 signal out, pin 6 ground). The output voltage 0 to +10 Vdc is proportional to the pump current 0 to 1 mA (e.g. -

Page 60: Pump Connection

Technical Information Fuse Holder and Voltage Changer Assembly Pump Connection The pump is connected to the controller rear panel via the high voltage connector by a coaxial high voltage cable assembly. High voltage can cause severe injury or death. Before installing or removing WARNING! the connector: Turn the power off. - Page 61 Technical Information Fuse Holder and Voltage Changer Assembly J001 Interlock Jach (A) Figure 14 Interlock Jack position MicroVac Controller User Manual / 87-900-089-01 (G) 61/72...

-

Page 62: Use

Technical Information General Make all vacuum manifold and electrical connections and refer to the ion pump instruction manual prior to operating the MicroVac controller. The accessory P001 connector should be left in position including the jumper NOTE between pin 3 and 7 if no external connection has been made. Before plugging in the controller power cable, be sure that the selected operating CAUTION! voltage matches the power source to avoid equipment damage. -

Page 63: Power Failure

Technical Information Power Failure In the event of a power failure (momentary or long period) the controller is switched off. When power is restored, the controller will automatically restart. Remote Control Mode Operation It is possible to remotely switch onb and off the high voltage using a permanent contact connected to pins 3 and 7 of J001 accessory connector with the mains power ON/OFF switch to ON. -

Page 64: Replacement

Technical Information Replacement Replacement General Replacement controllers are available on advance exchange basis through Agilent service/sales organization. WARNING! High voltage in the controller can cause severe injury or death. Before servicing, turn power off and remove the power cable. Troubleshooting No current/voltage LED bar graph lit with mains power ON but H.V. -

Page 65: Accessories And Spares Parts

Technical Information Accessories and Spares Parts Accessories and Spares Parts Tab. 3 Description Part number Mating accessory connector P001 03-648487 Fuse T1A (5 x 20 mm) 67.150410-01 Rack adapter 969-9191 Mains cable 120 Vac USA plug 03-660441-02 Mains cable 220 Vac European plug 03-660441-01 MicroVac Controller User Manual / 87-900-089-01 (G) 65/72... - Page 66 This document contains proprietary information of Agilent associates except as authorized by Agilent in a separate writing. This document and its information shall not be copied, used or disclosed to others, and shall be returned to Agilent upon request Agilent Technologies Italia S.p.A.

- Page 72 Request for Return Form Sales and Service Offices United States India Southeast Asia Agilent Technologies Agilent Technologies India Pvt. Ltd. Agilent Technologies Sales Sdn Bhd Vacuum Products Division Vacuum Product Division Vacuum Products Division 121 Hartwell Avenue G01. Prime corporate Park,...