Zenner zelsius C5-ISF Notice D'installation Et D'utilisation

Masquer les pouces

Voir aussi pour zelsius C5-ISF:

- Manuel de montage et d'installation (84 pages) ,

- Manuel de montage et d'utilisation (12 pages) ,

- Notice d'installation (52 pages)

Publicité

Les langues disponibles

Les langues disponibles

Liens rapides

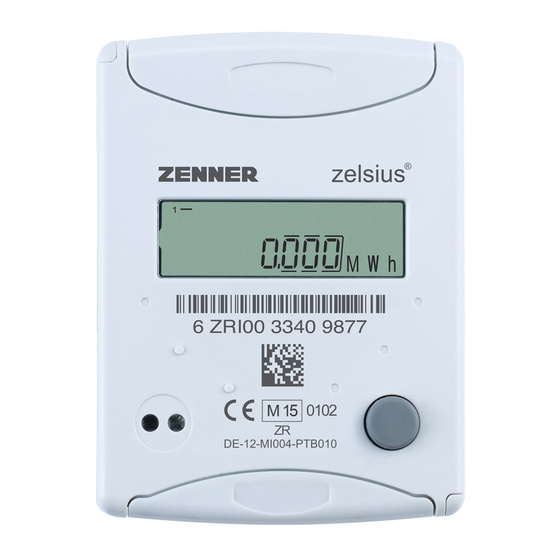

zelsius® C5 - ISF

D

Montage- und Bedienungsanleitung ............................... 2

Elektronischer, kompakter Wärme- und Kältezähler

mit Einstrahl-Durchflusssensor ISF

optional M-Bus, wM-Bus, LoRaWAN® und 3 Ein-/Ausgänge

q

0,6/1,5/2,5 m³/h

p

GB

Installation and operating instructions .........................14

Electronic compact meter for heating or cooling energy

with single-jet flow sensor ISF

optional with M-Bus, wM-Bus, LoRaWAN® and 3 inputs/outputs

q

0.6/1.5/2.5 m³/h

p

F

Notice d'installation et d'utilisation .............................. 26

PDF

Compteur électronique d'énergie thermique et de frigorie

avec mesureur à jet unique (ISF)

en option : M-Bus, wM-Bus, LoRaWAN® et 3 entrées/sorties en option

q

0,6/1,5/2,5 m³/h

p

Download

Notice d'installation

I

Istruzioni per il montaggio e l'utilizzo ........................... 38

Istruzioni per il montaggio

Contatore di calore compatto elettronico dotato di volumetrica

coassiale a getto unico

versioni M-Bus, wM-Bus, LoRaWAN® e con 3 ingressi / uscite

q

0,6/1,5/2,5 m³/h

p

Publicité

Sommaire des Matières pour Zenner zelsius C5-ISF

- Page 1 zelsius® C5 - ISF Montage- und Bedienungsanleitung ....... 2 Elektronischer, kompakter Wärme- und Kältezähler mit Einstrahl-Durchflusssensor ISF optional M-Bus, wM-Bus, LoRaWAN® und 3 Ein-/Ausgänge 0,6/1,5/2,5 m³/h Installation and operating instructions ......14 Electronic compact meter for heating or cooling energy with single-jet flow sensor ISF optional with M-Bus, wM-Bus, LoRaWAN®...

- Page 2 Deutsch Inhalt Lieferumfang ....................3 Technische Daten ..................3 MID-Konformitätserklärung................4 Sicherheitshinweise..................4 Elektromagnetische Störungen ..............4 Pflegehinweise ....................4 Montageanleitung ..................4 Sicherheitshinweise zur Montage ..............4 Einbau des Durchflusssensors (DFS) ............5 Einbau des Kugelhahns ................5 Montage Wärme-/Kältezähler ............... 5 Montage Temperaturfühler ................

- Page 3 Lesen Sie unbedingt die Monta- vermeiden Schäden. Prüfen Sie den ge- und Bedienungsanleitung vor Inhalt der Verpackung vor Montage der Installation / Inbetriebnahme. auf Vollständigkeit. Dadurch schützen Sie sich und Lieferumfang zelsius® C5 Kompakt Wärme- und/oder Kältezähler ■ Zwei Dichtungen ■...

- Page 4 Die Konformitätserklärung ist jedem Messgerät beigefügt. Neueste Infor- bei der Montage - Verbrühungsge- fahr! Den Zähler nicht an den Kabeln mationen zu diesem Produkt können unter www.zenner.de abgerufen tragen. werden. Die maximale Heizwassertemperatur im Durchflusssensor darf 90 °C nicht Sicherheitshinweise übersteigen.

- Page 5 nicht geeicht und darf daher nicht Nur neues Dichtmaterial verwen- ■ den, kein Hanf oder ähnliches! für Abrechnungszwecke im geschäft- Dichtflächen säubern und auf lichen Verkehr eingesetzt werden. Beschädigung kontrollieren. Hierfür sind zur Zeit Geräte mit einer Neuen Durchflusssensor fließrich- ■...

- Page 6 Nochmals prüfen, dass Messin- standstauchhülsen der zelsius ® gadapter in richtiger Kerbe sitzt zugelassen ist, finden Sie unter (nächste zum Kabel) – Kerbstift bündig eindrücken www.zenner.de – Montagehilfe abziehen Inbetriebnahme Temperaturfühler in die Ein- ■ baustelle einsetzen und bis zum Absperrorgane (Kugelhähne) ■...

- Page 7 Inbetriebnahmeprotokoll gemäß ■ !! WICHTIG !! PTB-Richtlinie TR K9 ausfüllen. Die Wahl des Einbauortes kann nur einmalig durchgeführt werden. Eine Hinweis: nachträgliche Änderung ist nicht Nur für Ausführungen mit program- möglich. mierbarem Einbauort für den Durchflusssensor (Bezeichnung Aktiviert wird die Auswahl mit dem „point of installation: see display“...

- Page 8 Beispiel: Programmierung der M-Bus-Adresse (optional) Ausgang 1 = Energieausgang Energieanzeige = XXXXX.XXX Anwahl der Anzeige „Adr0000“ ■ Letzte Stelle = 0,001 MWh = 1 kWh in Ebene 3 (für Zusatzeingänge Ausgangsimpuls = 1 kWh analog „Adr1“ bis „Adr3“) Taste für ca. 2 Sekunden drücken ■...

- Page 9 Die Funkschnittstelle ist bei Auslieferung immer deaktiviert. Zur Aktivierung des Gerätes ist keine Software erforderlich. Achtung! Bei zelsius C5 mit LoRa-Schnittstelle empfehlen wir zunächst die zum Gerät gehörenden Key-Informationen (DevEUI, Joi- nEUI und AppKey) auf Ihrer jeweiligen IoT-Plattform zu hinterlegen, bevor Sie das Gerät wie nachfolgend beschrieben aktivieren! Es ist lediglich der ab Werk immer aktivierte Sleep-Modus zu been- den: Geräte, die sich im Sleep-Modus befinden (Anzeige: SLEEP 1), sind mittels...

- Page 10 Einfaches Beispiel der Menüführung Ebene 1 Ebene 2 Wärmeenergie Wärmeenergie vom letzten (Hauptanzeige) Stichtag bis heute Kälteenergie Kälteenergie vom letzten Stichtag bis heute Segmenttest Aktueller Monatsverbrauch Wärmeenergie Datum Stichtag Aktueller Monatsverbrauch Kälteenergie Energie am Stichtag Aktuelles Monatsvolumen Kälteenergie am Stichtag Maximaler Durchfluss Volumen Maximaler Monats-...

- Page 11 Ebene 3 Ebene 4 Fühlerart und Einbauort DFS Funktion Impulswertigkeit Ausgang 1 Eingang 1 Seriennummer (bzw. die Funktion Impulswertigkeit rechten 8 Stellen der DevEUI) Ausgang 2 Eingang 2 DevEUI Funktion Impulswertigkeit (die linken 8 Stellen) Ausgang 3 Eingang 3 JoinEUI Restenergie opt.

- Page 12 Statusanzeigen / Fehlercodes Die Symbole in untenstehender Tabelle zeigen den Betriebszustand des Zählers eindeutig an. Sie erscheinen nur in der Hauptanzeige (Energie). Eine vorüber- gehende Anzeige des Warndreiecks kann durch besondere Betriebszustände der Anlage verursacht werden und bedeutet nicht immer eine Gerätestörung. Erst wenn das Symbol dauerhaft ansteht, sollte der Servicebetrieb informiert werden! Symbol...

- Page 13 Betriebsstätte in D-09619 Mulda, Talstraße 2 , kos- tenlos abgegeben werden. Zenner stellt in jedem Fall die fachgerechte Entsorgung sicher. ZENNER International GmbH & Co. KG Römerstadt 6 | 66121 Saarbrücken | Deutschland Telefon +49 681 99 676-30 E-Mail info@zenner.com...

- Page 14 English Contents Scope of supply.....................15 Technical data ....................15 MID - Declaration of Conformity ..............16 Safety instructions ..................16 Electro-magnetic interference ..............16 Care instructions ...................16 Installation manual ..................16 Safety instructions for installation ...............16 Installation flow sensor (FS) .................17 Installation of the ball valve .................17 Mounting heat/cooling energy meter ............17 Installation of the temperature sensors ............17 Installation with existing immersion sleeves ..........18...

- Page 15 Be sure to read the installation and damage. Check the contents of the operating manual before install- packing before installation to be ing / commissioning. This allows complete. you to protect yourself and prevent Scope of supply zelsius® C5 compact heat and cooling meter ■...

- Page 16 If you have questions, please direct Caution with discharge of hot water them to info@zenner.com during the installation – scalding danger! Do not carry the meter by the The declaration of conformity is cables.

- Page 17 Installation flow sensor (FS) Installation of the temperature sensors Mount ball valves up- and down- ■ stream of the flow sensor. The installation of the tempera- ■ Consider the correct installation ture sensors should be prefer- ■ point. Normally this is the return ably symmetrical and as direct (the colder pipe in heating sys- installation.

- Page 18 Mounting with plastic adapter: ■ – Insert the 2 halves of the plastic connector into the sensor’s three notches (crimps) and press them together. Use the mounting aid as position- ■ ing aid. Mounting with brass adaptor: ■ Mounting example –...

- Page 19 Fill in the putting into use report ■ !! IMPORTANT !! in accordance with PTB-Directive The choice of the place of installa- TR K9. tion can be carried out only once. A subsequent change is not possible. Note: Only for versions with program- The selection is being activated with mable place of installation of the the door symbol (top right of the...

- Page 20 Programming of M-Bus address colour connection signification (optional) white I/O 1 In-/Output 1 Select of the display „Adr 000“ in ■ level 3 (same for the additional yellow I/O 2 In-/Output 2 inputs „Adr1“ to „Adr3“). green I/O 3 In-/Output 3 Press the button for about 2 ■...

- Page 21 The radio interface is always deactivated at delivery. To activate the device, no software is required. Attention! For zelsius C5 with LoRa interface, we recommend at first to do the onboarding of the device on your respective IoT platform by putting in the key information belonging to the device (DevEUI, JoinEUI and AppKey) before activating the device as described below! Only the activated sleep mode has to be finished: Devices that are in sleep mode (Display: SLEEP 1) must be activated by at least five second press of the...

- Page 22 Simple example of the display menu Level 1 Level 2 Heat energy Heat energy difference from (Main display) last due date to now Cooling energy Cooling energy difference from last due date to now Segment test Heat energy difference from 1.

- Page 23 Level 3 Level 4 Sensor type and installation Pulse value Pulse value point of the flow sensor Output 1 Input 1 Serial number (or the right 8 Pulse value Pulse value digits of the DevEUI) Output 2 Input 2 DevEUI Pulse value Pulse value (the left 8 digits)

- Page 24 Status display / Error codes The symbols in the table below show the meter’s operational status. The status messages only appear in the main display (energy). The temporary display of the warning triangle can be caused by special operating states and does not always mean that the device is malfunctioning.

- Page 25 Therefore please contact the department of your local authority which is responsible for waste dis- posal. Alternatively a waste disposal via ZENNER is possible. Your local or municipal authority or the local waste disposal company can give you information relating the collec- tion points for your used equipment.

- Page 26 Français Contenu Contenu de livraison ...................27 Caractéristiques techniques ................27 Déclaration de conformité ..................28 Indications de sécurité ..................28 Perturbations électromagnétiques ..............28 Conseils d’entretien ....................28 Manuel d‘installation ..................28 Consignes de sécurité à respecter lors du montage ..........28 Installation du mesureur ..................29 Montage des vannes ...................29 Montage du compteur d’énergie thermique/ frigorifique........29 Connection des sondes de température ............29 Indications relatives au montage des doigts de gants existants .......30...

- Page 27 Veuillez impérativement lire le manuel éviterez tout dommage à votre appa- de montage et les instructions d’utili- reil. Vérifiez également que le contenu sation avant l’installation et la mise en de livraison est bien complet avant de route. Vous vous protégerez ainsi et procéder au montage.

- Page 28 Pour toutes les questions, veuillez relatives à l’installation électrique vous adresser à notre support tech- sont à respecter pour tout appareil nique zenner.france@zenner.com avec interface M-Bus. Attention en cas d’écoulement d’eau chaude durant le montage / Risque de graves brûlures La déclaration de conformité...

- Page 29 utilisé à des fins de facturation dans Démonter l’ancien mesureur de ■ des transactions commerciales. Pour volume / adaptateur. ce type d’utilisation des appareils Employez uniquement des maté- ■ avec un certificat d’examen de type riaux d’étanchéité neufs et sans séparé...

- Page 30 Passez un joint torique sur l’acces- ■ soire de montage (le 2ème joint est fourni uniquement en pièce de rechange) et à l’aide de l’acces- soire de montage, placez le joint torique par de légers mouvements de rotation à l’emplacement du montage (selon la norme DIN EN 1434).

- Page 31 Attendez pour la mise à jour de ■ !! IMPORTANT !! l’affichage des températures. Le choix du point d’installation ne Une fois la mise en service effec- ■ peut être fait qu’une seule fois. Une tuée, sécurisez l’appareil. modification ultérieure n’est pas Remplissez le protocolle de mise ■...

- Page 32 Exemple: Programmation de l’adresse M-Bus Sortie 1 = Sortie énergie (en option) Valeur d’énergie affichée = XXXXX.XXX Sélectionnez l‘affichage „Adr0000“ ■ Dernière décimale = 0,001 MWh = 1 kWh en Niveau 3 (pour des entrées Impulsion de sortie = 1 kWh supplémentaires analogue „Adr1“...

- Page 33 L'interface radio est toujours désactivée à la livraison. L‘activation de l’appareil ne nécessite pas de logiciel. Attention ! Pour zelsius C5 avec l’interface LoRa, nous vous recommandons de commencer par enregistrer les informations de clé appartenant au périphérique (DevEUI, JoinEUI et AppKey) sur votre plate-forme IoT respective avant de l'activer, comme décrit ci-dessous! Il faut néanmoins désactiver le mode veille qui est activé...

- Page 34 Exemple simple de navigation dans le menu Niveau 1 Niveau 2 Energie thermique Energie thermique (Affichage principal) (Différence date /date de mise en service) Energie frigorifique Energie frigorifique (Différence date /date de mise en service) Test segment Consommation du mois actuel en énergie thermique Date repère Consommation du mois actuel en...

- Page 35 Niveau 3 Niveau 4 Type de sonde et emplace- Valeur d’impulsion Valeur d'impulsion ment sur installation Sortie 1 Entrée 1 Numéro de série (ou les 8 Valeur d’impulsion Valeur d'impulsion derniers chiffres du DevEUI) Sortie 2 Entrée 2 DevEUI (les 8 premiers Valeur d’impulsion Valeur d'impulsion chiffres)

- Page 36 Affichage des états / Codes d’erreur Les symboles figurant dans le tableau ci-dessous permettent d’indiquer très clairement l’état de fonctionnement du compteur. Ils apparaissent seulement sur l’écran principal (énergie). Un affichage temporaire du symbole d’avertis- sement peut être provoqué par des états particuliers de l’installation et ne signale pas systématiquement une panne de l’appareil.

- Page 37 à la mairie locale, auprès des déchetteries locales. Zenner assure dans tous les cas une élimination professionnelle. Compteurs ZENNER S.A.R.L. 7, rue Gustave Eiffel / 87410 Le Palais sur Vienne / France Téléphone 05 55 38 37 09...

- Page 38 Italiano Indice Fornitura ..................... 39 Dati tecnici ..................39 Conformità alla normativa MID ............40 Indicazioni di sicurezza ............... 40 Interferenze elettromagnetiche ............40 Avvertenze d’uso................. 40 Manuale di installazione ..............40 Indicazioni di sicurezza relative all‘installazione ....... 40 Indicazioni per l’installazione della parte volumetrica ..... 41 Installazione della valvola a sfera ............

- Page 39 Leggere attentamente ed integral- permetterà di proteggersi ed evitare mente le istruzioni di montaggio e di possibili danni. Controllare che il con- utilizzo prima di procedere all’installa- tenuto della confezione sia completo zione o alla messa in servizio. Questo prima di incominciare l’installazione. Fornitura zelsius®...

- Page 40 Conformità alla normativa MID gli anni di validità della taratura. Le Il zelsius® C5 a ultrasuoni è realizzato riparazioni possono essere eseguite e testato in conformità alla normativa solo dal produttore o da partner di Europea 2014/32/EU (MID). Secondo assistenza autorizzati. la quale non serve il punzone della Manuale di installazione taratura sullo strumento, ma viene...

- Page 41 Indicazioni per l’installazione della Montare la volumetrica nuova in ■ parte volumetrica base alla direzione di flusso e alla A monte e a valle della parte volu- posizione. ■ metrica si devono installare delle Girare la parte elettronica del con- ■...

- Page 42 Montaggio con l’adattatore in ■ plastica: – Collocare entrambe le metà della filettatura di plastica nelle tre scanalature della sonda e preme- re in modo deciso. Avvalersi dello strumento di ■ supporto. Montaggio con adattatore in ■ Esempio di montaggio ottone: –...

- Page 43 Attendere l’aggiornamento della ■ Installazione sulla mandata: temperatura sul display. Al termine della messa in funzione ■ apporre i sigilli contro la rimozione non autorizzata. Compilare il verbale della messa in ■ funzione secondo la disposizione !! IMPORTANTE !! del PTB TR K9. La scelta del punto di installazione si può...

- Page 44 Esempio: Programmazione dell’indirizzo Uscita 1 = uscita energia elettrica M-Bus (su richiesta) Indicatore d’energia = XXXXX.XXX Scelta del display „Adr0000“a ■ Ultima cifra = 0,001 MWh = 1 kWh livello 3 (come per gli inputs ag- Uscita impulsiva = 1 kWh giuntivi „Adr1“fino „Adr3“).

- Page 45 L’interfaccia radio è sempre disattivata al momento della consegna. Per attivare il dispositivo non è necessario alcun software. Attenzione! Per zelsius C5 con interfaccia LoRa, si consiglia come prima operazione di registrare il dispositivo sulla propria piattaforma IoT inserendone le informazioni chiave (DevEUI, JoinEUI e AppKey) prima di attivarlo come descritto di seguito.

- Page 46 Semplice esempio del Menu Livello 1 Livello 2 Energia termica Energia termica dall’ultimo (Display principale) “giorno fisso” d’azzeramento fino ad oggi Energia di raffrescamento Energia di raffrescamento dall’ultimo “giorno fisso” d’azzeramento fino ad oggi Test dei segmenti Calore differenza dal 1 di questo mese ad oggi Data del giorno fisso d’azzeramento Raffrescamento differenza dal 1 di questo...

- Page 47 Livello 3 Livello 4 Tipo di sonda e punto di Funzione Valore impulsivo installazione della volumetrica Uscita 1 Ingresso 1 Numero di serie (o le 8 cifre a Funzione Valore impulsivo destra del DevEUI) Uscita 2 Ingresso 2 DevEUI (le 8 cifre a sinistra) Funzione Valore impulsivo Uscita 3...

- Page 48 Display dello status / codice errore I simboli nella tabella sottostante indicano lo status del contatore in modo inequivocabile. Lo status è rilevabile solo sul display principale (Energia). Il lampeggiamento della spia triangolare può essere causato da particolari condizioni dell’impianto e non indica necessariamente un guasto dell’ap- parecchio.

- Page 49 Per ulteriori informazioni potete contattare la ns. sede al seguente numero telefonico: 051 198 733 80. ZENNER assicurerà sempre di informarvi sul corretto smaltimento. Zenner Srl Via Marzabotto 85 | I - 40050 Funo di Argelato (BO) | Italia...

- Page 50 Notice...

- Page 52 ZENNER International GmbH & Co. KG Römerstadt 6 66121 Saarbrücken Germany Telefon +49 681 99 676-30 Telefax +49 681 99 676-3100 E-Mail info@zenner.com Internet www.zenner.com...

- Page 53 GE552Y215-216-217 Heat meter, compact version USER MANUAL PREMISE The installation must be carried out by qualified personnel only. The manufacturer does not assume any responsibility for improper installation or damages caused by third parties. WARNING The meter contains potentially dangerous batteries: handle carefully and do not dump in the environment.

- Page 54 INTRODUCTION The model GE552Y215-6-7 is a compact heat meter that measures the thermal energy used in the heating and cooling systems. The meter allows to measure the thermal energy passing into a hydraulic circuit used for heating and\or for cooling, it let also the acquisition of the volume measured by up to 2 water meters equipped with pulse emitter.

- Page 55 INSTALLATION HYDRAULIC PART BEFORE MOUNTING Before the meter installation make sure that the two ends of the inlet and outlet pipe are perfectly aligned, clean them with the utmost care. Moreover, make sure there is a suitable filter placed at the inlet and that clean and undamaged gaskets are inserted on both sides.

- Page 56 ALLOWED MOUNTING POSITIONS All the versions of the heat meters can be installed both horizontally and vertically. For a better performance it is preferable, however, the horizontal installation, with the turbine axis perpendicular to the ground and the reading mechanism facing upwards. Position allowed.

- Page 57 ELECTRONIC UNIT Open the electronic unit by leveraging on the two hooks [1] and remove the cover [2]. For the specific connection instructions, refer to the appropriate sections included in this manual. After the installation, connection, configuration and commissioning, close the cover and apply adhesives sealing.

- Page 58 TEMPERATURE SENSORS INSTALLATION The heat meter is equipped with two PT1000 temperature sensors in accordance with the MID 2014/32/CE and EN1434 approvals. For a proper installation, always proceed in accordance with the guidelines prescribed by law. In the standard version (return pipe mounting position), the return sensor is already built into the brass body.

- Page 59 BALL VALVE INSTALLATION For this kind of installation, first of all it is necessary to insert the temperature sensor in the threaded nut [1] and insert the closing pin [2]. Unscrew the plug screw from the valve and place proper gaskets [3] (included in the package) in order to guarantee a safe installation.

- Page 60 EXTERNAL CONNECTIONS INSTALLATION PREMISE The rear cable glands must be used correctly in order to avoid malfunction and/or premature discharge of the batteries. In bad use, the device's IP54 protection can no longer be considered valid. The cables must be proportionate to the size of the hole made to pass them. The manufacturer does not assume any responsibility for improper installation or damages caused by third parties.

- Page 61 CONNECTIONS AVAILABLES The meter gives the following possibilities of external connections: 2 pulse inputs for connecting of two water meters with pulse emitters (the liter\pulse ratios supported are 0.1 – 0.25 – 1- 2.5 – 10 – 25 – 100 – 250 – 1000) 1 pulse output for the sending of the thermal energy counting (heating only) for the connection to a pulse acquisition system (the KWh\pulse ratios selectable are 1 –...

- Page 62 M-BUS NETWORK CONNECTION The inputs/outputs “M-Bus” (24 and 25) are dedicated to the meter connection with an M-Bus network cable. For the connection is not necessary to respect the polarity, although it is advisable to keep the same polarity on the entire cable network. Warning: the M-Bus network is using voltage that can damage the device when applied to terminals dedicated to other functions, so be careful when connecting to this interface.

- Page 63 VOLUME METERS C1/C2IN CONNECTION The inputs C1 IN (51, 52, 53) and C2 IN (54, 55, 56) are dedicated to the flowmeters for hot and cold sanitary water. The heat meter is compatible with flowmeters with pulse output OC (open collector) or OA (reed), with pulse value “liters/pulse”...

- Page 64 FUNCTIONALITY The heat meter GE552Y215-6-7 is equipped with dedicated sections for the thermal energy measurement of a heating/cooling (on request) system and for the volume measurement of the hot/ cold sanitary water system. The meter is suitable for two-pipe domestic systems, in boiler room installations or any other compatible application.

- Page 65 DISPLAY AND BUTTONS The heat meter is equipped in the front with a liquid crystal display and two buttons (T1 and T2), useful for the configuration of the parameters and for the readings. 1) Eight-digit numeric field; 2) Single-digit numeric index (menu level); 3) Heating data index;...

- Page 66 PROGRAMMING MENU The programming menu is useful for the ordinary programming of the meter and for configured data verification. PROGRAMMING MENU ACCESS To enter the programming menu, press the T1 button and select level 3. Then keep the T2 button pressed for more than 3 seconds.

- Page 67 Confirm the selected parameter by holding the T2 button for more than 3 seconds, thus moving to the next parameter. 3) The third parameter that has be configured is the pulse value "k" of the C2 cold/hot water meter. The value can be selected by using the button T1: 0.1–0.25–1–2.5–10–25–100–250–1000 L/imp Confirm the selected parameter by holding the T2 button for more than 3 seconds, thus moving to the next parameter.

- Page 68 Confirm the selected parameter by holding the T2 button for more than 3 seconds, thus moving to the next parameter. 7) The seventh parameter that has be configured is the primary address of the Wired M-Bus (M-Bus) of the heating data. Select the digit using the T2 button and change the single numbers with the T1 button. Confirm the selected parameter by holding the T2 button for more than 3 seconds, thus moving to the next parameter.

- Page 69 CONSULTING MENU The consulting menu is divided in six levels by a numeric index, always shown in the left-upper part of the display. By pressing the T1 button it is possible to choose the desired level, and by pressing the T2 button it is possible to consult the sublevels of the preset level.

- Page 70 LEVEL 2: ACTUAL ACCOUNTING VALUES 2.1 Actual power 2.2 Actual flow rate 2.3 Inlet flow temperature 2.4 Return flow temperature 2.5 Temperature difference GE552Y215-6-7 User Manual v1.9.1 ENG - 18...

- Page 71 LEVEL 3: SETTINGS (DISPLAYING ONLY) 3.1 Serial number 3.2 Firmware version 3.3 Communication Firmware version 3.4 Current Date 3.5 Liters/pulse value for input flow sensor (set during production process) 3.6 Measurement unit (0= MWh, 1= GJ) 3.8 Liters/pulse value for first input flow meter (C1) 3.9 Starting value first input flow meter (C1) 3.11 Liters/pulse value for second input flow...

- Page 72 3.16 M-Bus Secondary address (Heating) 3.17 M-Bus Primary address (Heating) 3.18 M-Bus Secondary address (Cooling) 3.19 M-Bus Primary address (Cooling) LEVEL 3: SETTINGS (CONFIGURATION) The setting of the parameters can be enabled by pressing T2 for 3 seconds while viewing one of the points of the level 3.

- Page 73 3s.10 Liters/pulse value setting for heating pulse output (Hot out) 3s.12 M-Bus Secondary address setting (Heating) 3s.13 M-Bus Primary address setting (Heating) 3s.14 M-Bus Secondary address setting (Cooling) 3s.15 M-Bus Primary address setting (Cooling) 3s.16 Saving parameters settings and exit 1 = save and exit, 0 = don’t exit GE552Y215-6-7 User Manual v1.9.1 ENG - 21...

- Page 74 LEVEL 4: MEMORY DAY DATA 4.1 Memory Day 4.2 Accounted Energy (heating) – cumulative value at memory day 4.3 Accounted Energy (cooling) – cumulative value at memory day 4.4 Accounted Volume (C1) – accounted volume at memory day (optional) 4.5 Accounted Volume (C2) – accounted volume at memory day (optional) Memory day setting: View any of the points in the level 4...

- Page 75 5.3 Historical data storage (up to 26 possible values, saving at the end of the month) 5.3.1 Accounted Energy (heating) – cumulative value at historical memory day 5.3.2 Accounted Energy (cooling) – cumulative value at historical memory day 5.3.3 Accounted Volume (C1) – accounted volume at historical memory day (optional) 5.3.4 Accounted Volume (C2) –...

- Page 76 COMMISSIONING Premise: the procedures explained in this paragraph must be carried out only after the conclusion of the installation phases, the connection procedures and after the testing of the hot/cold water and heating/cooling systems. Warning: once the meter has accounted energy and volumes, some of the settable parameters will no longer be editable.

- Page 77 Here is a list of all the error codes: Error Description Prescription Notes One of the two temperature sensor Check the integrity and the Return the meter to the Err101 cables is cut; connection of the temperature manufacturer. Resettable via At least one cable is disconnected sensor cables.

- Page 78 BATTERY AND REPLACEMENT PROCEDURES The heat meter constantly checks the battery status (average lifetime: 10 years) and signals the imminent discharge showing the icon on the display. The signal will be shown one year before the complete discharge. For the replacement, contact the manufacturer. Warning: the meter is equipped with non-rechargeable batteries, that can be dangerous when used improperly.

- Page 79 GE552Y215-6-7 Model Battery supply Power supply Li-SoCl2 Lithium-thionyl chloride, 3,6V 6Ah 10 years +1 (depending Battery type on the version) Battery Life 5 ÷ 55°C Operating temperature range -10 ÷ 55°C Storage temperature range Dimensions 112 x 78 x 76.5mm Weights 635g (DN15);...

- Page 80 Information for correct disposal of the product This product falls into the scope of the Directive 2012/19/EU concerning the management of Waste Electrical and Electronic Equipment (WEEE). This product shall not be disposed into the domestic waste as it is made of different materials that have to be recycled at the appropriate facilities. Inquire through the municipal authority regarding the location of the ecological platforms to receive the product for disposal and its subsequent correct recycling.