Publicité

Les langues disponibles

Les langues disponibles

Liens rapides

293 Wright Street, Delavan, WI 53115

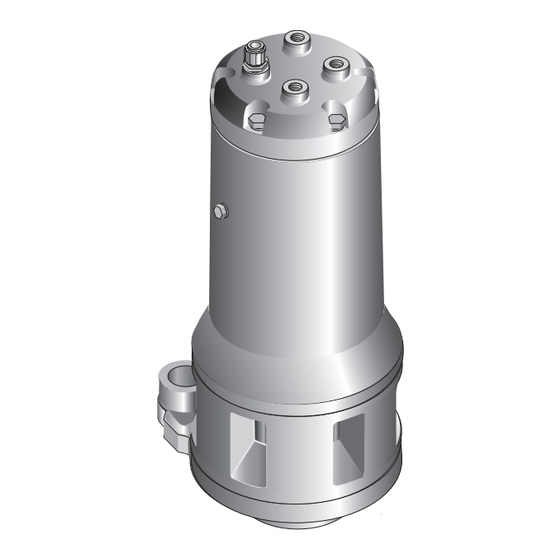

Grinder Pumps

INSTALLATION, OPERATION, & PARTS MANUAL

SAFETY INFORMATION

Carefully read and follow all safety instructions in this

manual or on pump.

This is the safety alert symbol. When you see this

symbol on your pump or in this manual, look for one of the

following signal words and be alert to the potential for

personal injury!

warns about hazards that will cause serious

personal injury, death or major property damage if ignored.

warns about hazards that can cause serious

personal injury, death or major property damage if ignored.

warns bout hazards that will or can cause

minor personal injury or property damage if ignored.

The word NOTICE indicates special instructions which are

important but not related to hazards.

1. Read these rules and instructions carefully. Failure to

follow them could cause serious bodily injury and/or

property damage.

2. Check your local codes before installing. You must com-

ply with their rules.

3. Vent sewage or septic tank according to local codes.

4. Disconnect electrical power and keep hands away from

pump inlet opening when working on or handling pump

for any reason. Do not use automatic reset controls with

this pump. Accidental rotation of the cutter with hands in

the cutter area can cause severe injury.

5. Always keep pump properly serviced and maintained.

6. Use pump for designed task – that is, pumping domestic

sewage and waste water containing solids. Do not pump

metal particles, rocks, or other hard objects.

7. Do not pump corrosive or flammable liquids with this

pump.

DESCRIPTION

These submersible wastewater pumps are designed for

sewage, effluent and wastewater removal or transfer, sump

drainage, dewatering, flood control and for circulation.

SGC12, SGC13 and SGC20 Series Models include internal

circuitry that detects seal leakage and overheating of wind-

ings. This circuitry is also available on the SG12 and SG13

Series Models. Other options available include lift-out sys-

tem components, control panels, switches and alarms.

© 2008

All manuals and user guides at all-guides.com

SPECIFICATIONS

Power Supply Required: . . . . . . . . . . . . . . .208/230-230/460

Motor Duty: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Intermittent

Maximum Liquid Temperature: . . . .1 Phase - 40° C (104° F)

Discharge Adapter:

Power Cable: . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Type STO

Volute, Impeller and Pump Body: . . . . . . .Class 30 Cast Iron

O-Rings and Elastomer Part of Shaft Seal: . . . . . . . .Buna-N

Shaft Seal Faces: . . . . . . . . . . . . .Carbon and Ceramic with

Fasteners in contact with liquid

being pumped: . . . . . . . . . . . . . . . . . . . . . . . .Stainless Steel

Grinder Assembly: . . . . . . . . . . . . . . .17-4ph Stainless Steel

MODEL NUMBER CROSS

REFERENCE CHART

SG12/SGC12, SG13/SGC13

and SGC20 Series

SG12/SGC12/SG13/SGC13 Series . . . . . . . . . . . . . .1-1/4"

SG20/SGC20 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . .2"

New Model Number

SG12200225M

SG12200325M

SG13200225M

SG13200325M

SGC12200225M

SGC12200325M

SGC13200225M

SGC13200325M

SGC20300225M

SGC20300325M

SGC20500225M

SGC20500325M

SGC20750325M

1929 0895

3 Phase - 60° C (140° F)

Stainless Steel Trim

Original Model Number

12SG1-1012

12SG3-1012

12SG1-1011

12SG3-1011

12SGC1-1012

12SGC3-1012

12SGC1-1011

12SGC3-1011

20SG1-2013

20SG3-2013

20SG1-2012

20SG3-2012

20SG3-2011

S500 (4/23/08)

Publicité

Sommaire des Matières pour STA-RITE SG12 Serie

- Page 1 All manuals and user guides at all-guides.com SG12/SGC12, SG13/SGC13 and SGC20 Series 293 Wright Street, Delavan, WI 53115 Grinder Pumps 1929 0895 INSTALLATION, OPERATION, & PARTS MANUAL SAFETY INFORMATION SPECIFICATIONS Carefully read and follow all safety instructions in this Power Supply Required: ....208/230-230/460 manual or on pump.

- Page 2 All manuals and user guides at all-guides.com MOTOR SPECIFICATIONS PIPING DIMENSIONAL GUIDE Motor Minimum Vert. Disch. Pipe Length Model Voltage/ Max. Load Circuit Number Phase Amps Req.(Amp) Locking Rail Length SG12200225M 208-230/1 12.0 SG12200325M 208-230/460/1 6.6-6.0/3.0 10/10 SG13200225M 208-230/1 14.0 Basin Discharge SG13200325M...

- Page 3 All manuals and user guides at all-guides.com PIPING DIMENSIONAL SG12/SGC12 SGC20 SG13/SGC13 GUIDE FOR GUIDE-RAIL 12SG/12SGC 20SG LIFT-OUT SYSTEM 7-15/16'' 5-1/8'' (202mm) (130mm) Locking 17-5/8'' Rail (448mm) 23-1/2" (597mm) Guide Rails Connection Height of 8-1/4" Stationary (210mm) 10-5/8 Flange (270mm) 1930 0895 10-9/16"...

- Page 4 All manuals and user guides at all-guides.com 1938 0895 1937 0895 1939 0895 SG12/SGC12/SG13/SGC13 SGC20 NOTICE The assembly sequence for the moveable parts (Steps 9 and 10) differs from SG12/SGC12/ SG13/SGC13 to SGC20 models. Follow the sequence that is correct for your pump.

- Page 5 When tight, the movable flange should point directly If a Sta-Rite control panel is not used, install a control panel away from you (that is, the check valve and the flange with circuit breaker or fused disconnect as required by local should be at right angles to each other).

- Page 6 Power Cable 230 VOLTS 460 VOLTS Black & White Single phase units & that are not installed & with Sta-Rite control Ground panels require a Control capacitor/overload Cable (16-4) T4,T5,T6 T4 & T7 package. Purchase T5 & T8 Not Used...

- Page 7 All manuals and user guides at all-guides.com Three Phase: NEMA design B with Class F insulation. MAINTENANCE Suitable for operation in liquids with a maximum temperature The Key numbers given in these procedures refer to the of 60°C (140°F). exploded views. See page 8 for SG12/SGC12/ Check rotation before installing pump in sump.

- Page 8 All manuals and user guides at all-guides.com Shaft Seal Disassembly: 2. Clean out the seal cavity in the back plate and press a new ceramic seal head into place in the seal plate. Be 1. Follow steps 1 through 4 under “Grinder Disassembly”. sure that you do not scratch or otherwise damage the 2.

- Page 9 All manuals and user guides at all-guides.com Guide Rail Lift-out System Repair Parts 1946 0895 For Series: For Series: For Series: For Series: SG12 SG12 SGC12 SGC12 SG13 SG13 SGC13 SGC20 SGC13 SGC20 Part Description W52439L W52440L Part Description W52439L W52440L Eyebolt W52919...

- Page 10 All manuals and user guides at all-guides.com 1944 0895...

- Page 11 All manuals and user guides at all-guides.com Repair Parts List SG12/SGC12/SG13/SGC13 Grinder Pumps SG12 SGC12 Part SG13 SGC13 Description Qty. Part No. Part No. 5/16-18x1 Hex Head Cap Screw SS 10411 10411 5/16 Lockwasher SS S23088 S23088 Terminal Cover Assembly W52016L W52457L O-Ring...

- Page 12 All manuals and user guides at all-guides.com 1945 0895...

- Page 13 All manuals and user guides at all-guides.com SGC20 Repair Parts List Part No. Part Description Qty. SGC20300225M SGC20500225M SGC20300325M SGC20500325M SGC20750325M 3/8-16x1-1/4” Hex Hd Cap Screw, SS S23568 S23568 S23568 S23568 S23568 3/8” Lockwasher, SS S23036 S23036 S23036 S23036 S23036 Terminal Cover Assemby W52017L W54002L...

- Page 14 All manuals and user guides at all-guides.com LIMITED WARRANTY STA-RITE warrants to the original consumer purchaser (“Purchaser” or “You”) of the products listed below, that they will be free from defects in material and workmanship for the Warranty Period shown below.

- Page 15 All manuals and user guides at all-guides.com Séries SG12/SGC12, SG13/SGC13 et SGC20 293 Wright Street, Delavan, WI 53115 Pompes broyeuses NOTICE D’INSTALLATION, DE 1929 0895 FONCTIONNEMENT ET DES PIÈCES DÉTACHÉES SÉCURITÉ les inondations et pour la circulation. Les modèles des séries SGC12, SGC13 et SGC20 comprennent des circuits internes qui Lire et suivre attentivement toutes les consignes de sécurité...

- Page 16 All manuals and user guides at all-guides.com SPÉCIFICATIONS DU MOTEUR GUIDE DES DIMENSIONS DES TUYAUX Charge Longueur verticale du Vert. Disch. maximum Circuit tuyau de refoulement Pipe Length en ampères minimum Numéros Tension/ sur le requis (en Longueur de la glissière de blocage Locking Rail Length des modèles...

- Page 17 All manuals and user guides at all-guides.com GUIDE DES DIMENSIONS SG12/SGC12 SGC20 SG13/SGC13 DES TUYAUX DU SYSTÈME 12SG/12SGC 20SG 7 15/16 po DE LEVAGE À GLISSIÈRES 5 1/8 po 7-15/16'' 5-1/8'' (202 mm) (202mm) (130 mm) (130mm) DE GUIDAGE 17 5/8 po 17-5/8'' (448 mm) (448mm)

- Page 18 All manuals and user guides at all-guides.com 1938 0895 1937 0895 1939 0895 SG12/SGC12/SG13/SGC13 SGC20 NOTA e de montage L’ordr des pièces mobiles (opérations 9. et 10.) des modèles des séries SG12/SGC12/SG13/ SGC13 est différent de celui des modèles de la série SGC20. Suivre l’ordre corre- spondant à...

- Page 19 Lorsqu’elle sera serrée, la bride mobile devra Si un panneau de commande Sta-Rite n’est pas utilisé, installer un être orientée directement à l’opposé de la personne qui panneau de commande doté d’un disjoncteur ou d’un sectionneur procède à...

- Page 20 Câble de Control Cable commande neau de commande (16-4) (16-14) T4,T5,T6 T4 & T7 Sta-Rite n’est pas Pas utilisé Not Used T5 & T8 Noir Black installé. Se reporter au Pas utilisé Not Used Thermal Sensor T6 &...

- Page 21 All manuals and user guides at all-guides.com Triphasés : NEMA, conception B, isolant de classe F. Pour les liquides ENTRETIEN dont la température maximum ne dépasse pas 60 °C (140 °F). Les numéros de référence qui suivent se rapportent aux vues Avant d’installer la pompe dans le puisard, vérifier son sens de rota- éclatées.

- Page 22 All manuals and user guides at all-guides.com Démontage des joints de l’arbre : Nettoyer la cavité du joint pratiquée dans la plaque d’appui, puis pousser une tête de joint en céramique neuf en place, Suivre les opérations 1 à 4 figurant sous la rubrique « dans la plaque d’étanchéité.

- Page 23 All manuals and user guides at all-guides.com Pièces de rechange du système de levage à glissières de guidage 1946 0895 pour les séries pour les séries SG12 SGC12 SG13 SGC13 SGC20 W52439L W52440L Réf. Désignation des pièces W52919 W52918 Boulon à oeil W52298F W52068F Support du tuyau de refoulement...

- Page 24 All manuals and user guides at all-guides.com 1944 0895...

- Page 25 All manuals and user guides at all-guides.com Liste des pièces de rechange Pompes broyeuses des séries SG12/SGC12/SG13/SGC13 Nos. de pièce Nos. de pièce des séries des séries SG12 SGC12 Réf. Désignation des pièces Qté SG13 SGC13 Vis à chapeau à tête hexagonale en acier inoxydable de 5/16-18 x 1 10411 10411 Rondelle-frein en acier inoxydable de 5/16...

- Page 26 All manuals and user guides at all-guides.com 1945 0895...

- Page 27 All manuals and user guides at all-guides.com Liste des pièces de rechange des modèles de la série SGC20 Nos de pièce des séries Réf. Désignation des pièces Qté SGC20300225M SGC20500225M SGC20300325M SGC20500325M SGC20750325M Vis à chapeau à tête hexagonale en acier inoxydable de 3/8-16 x 1/4 de po S23568 S23568...

- Page 28 Le seul recours de l’Acheteur et la seule responsabilité de STA-RITE consistent à réparer ou à remplacer (au choix de STA-RITE) les produits qui se révéleraient défectueux. L’Acheteur s’engage à payer tous les frais de main-d’œvre et d’expédition du produit couvert par sa garantie et de s’adresser au concessionnaire-installateur ayant procédé...