Publicité

Les langues disponibles

Les langues disponibles

Liens rapides

INSTALLATION INSTRUCTIONS

Note: Wires connecting between box(es) and from transformer must

be protected from abrasion, and being pulled at connections. They

also may have to be fished through at a later stage of construction.

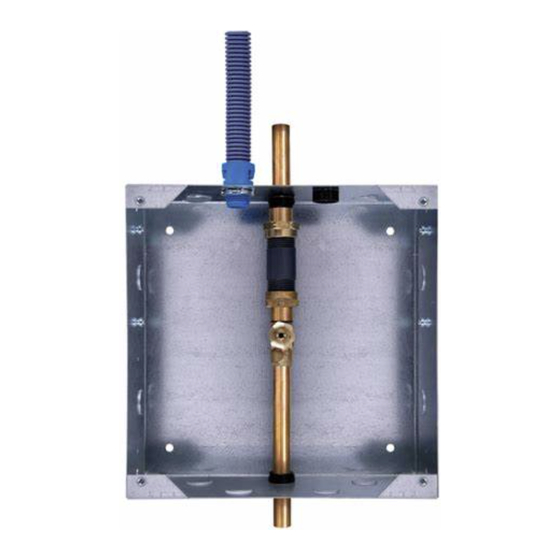

Depending on installation, the cable bushings included may be

replaced by installer supplied 1/2" conduit. Rough-in box as per

Figure 1.

Note: Conduit can be permanently bent to hold shape.

The transformer is to be installed in an adjacent accessible space.

(Do NOT install the transformer inside the control box.) Cable

from the transformer to the driver board/controller may be roughed

in at this time depending on installation. Use cable which complies

to local electrical codes for a 1 amp load. No.18 is usually sufficient.

HARDWIRE OR BATTERY

: If recessed box is supplied, rough in

as per Figure 1. The most vandal resistant installation is when the

control box is as close to the bottom of the sink as feasible. For wall

hung sink installation, sensor conduit rough in should be directly

under the basin to minimize sensor cord exposure. Rough in

drainage. Rough in water supply to 10" control box inlets and to

spout connection. Finish walls.

Valve spacer is for temporary use only for flushing of system.

Must be replaced with solenoid (Fig. 2 & 3).

FLUSH SYSTEM/SET TEMPERATURE

Remove coverplate from control box. Open screwdriver stop(s) to

flush installation for 1 minute minimum.

A Run water for a sufficient time so the hot and cold water supplies

are as hot and cold as they will get.

B Thermostatic Mixing Valve (Fig. 3).

To adjust the mixed outlet temperature of the valve, remove

the cap to gain access to the adjusting spindle. The spindle

should be rotated towards the "C" side to reduce the temper-

ature and towards the "H" side to increase the temperature -

until the desired set point is reached (refer

to Fig. 4).

Periodic Inspection/Maintenance - We

recommend that this valve is checked at least

once per year to ensure its continued function.

For installations with poor or unknown water

quality, or other adverse supply conditions, it

may be necessary to check the valve at more

frequent intervals. The temperature should be

checked at the same outlet as was used for

commissioning in the first instance. If the

temperature is more than 3°F from the comm-

issioning in temperature, refer to the included

Maintenance and Installation Guide.

C Close stop(s).

(Do not over torque stop).

Fig. 4

Towards

"H" side to

increase

Towards

temperature

"C" side

to reduce

temperature

TMV Repair Kit

061137A - Adjustment Wrench

063164A - Check Valves (2/pkg)

Installation should be in accordance with local

plumbing and electrical codes.

FLUSH ALL PIPES THOROUGHLY BEFORE

INSTALLATION.

Remove suitable knockout(s) in box(es) and insert

cable bushing(s).

Fasten box to

framing using

holes provided

inside of box

257mm

(10.13")

Control Box

Rough-in box

to be installed

(flush to 1/4")

to finished wall

*

The rough 10" cover plate is intended for temporary use only and must be replaced

with permanent 12" plate after rough-in stage is complete.

The 12" permanent plate is included on the applicable "Trim" models.

If a "Trim" model was not ordered, repair parts 060577A (12" permanent plate) and

060073A (4 screws & driver bit) must be ordered separately.

Control Box #1

Flexible Sensor Cord

Conduit (supplied on

Recessed Mount Box)

063135A

Stop

w w w . s p e c s e l e c t . c o m

ELAVT0001ARI

ELAVT0008ARI

Finished

Wall

Flexible, Sensor

Cord Conduit

1/2" sweat connection

305mm (12")

Stainless Steel

Cover Plate

102mm (4")

Fig. 2

Control Box #8

Hot Inlet

1/2" Sweat

1/2" Sweat

Outlet

Tempered Water

(By Others)

063135A

Stops

Inlet:

1/2" Sweat

Fig. 1

356mm

(14")

SUPPLIED:

max.

1/2" Sweat

Outlet from Box

BALANCE BY OTHERS

*

Product supplied as

shown by solid lines.

All items shown by

dotted lines supplied

by other or Trim

Package.

Flexible Sensor Cord

Conduit (supplied on

Recessed Mount Box)

Cold Inlet

1/2" Sweat

1/2" Sweat

Outlet

063179A

Thermostatic Mixing Valve

with checks and gaskets

210319 Rev. A

Fig. 3

Publicité

Sommaire des Matières pour Delta ELAVT0001ARI

- Page 1 ELAVT0001ARI Installation should be in accordance with local plumbing and electrical codes. FLUSH ALL PIPES THOROUGHLY BEFORE ELAVT0008ARI INSTALLATION. Remove suitable knockout(s) in box(es) and insert cable bushing(s). INSTALLATION INSTRUCTIONS Fig. 1 Note: Wires connecting between box(es) and from transformer must be protected from abrasion, and being pulled at connections.

- Page 2 ELAVT0001ARI L’installation doit être conforme aux Codes de plomberie et d’électricité locaux. VIDER SOIGNEUSEMENT TOUS LES TUYAUX ELAVT0008ARI AVANT DE PROCÉDER À L’INSTALLATION. Enlevez les entrées défonçables requises et insérer les bagues de cable. INSTRUCTIONS D’INSTALLATION Fig. 1 Remarque : Les câbles mis en circuit entre le ou les boîtiers et du trans- formateur doivent être protégés contre l’abrasion et tirés aux endroits où...