Table des Matières

Publicité

Liens rapides

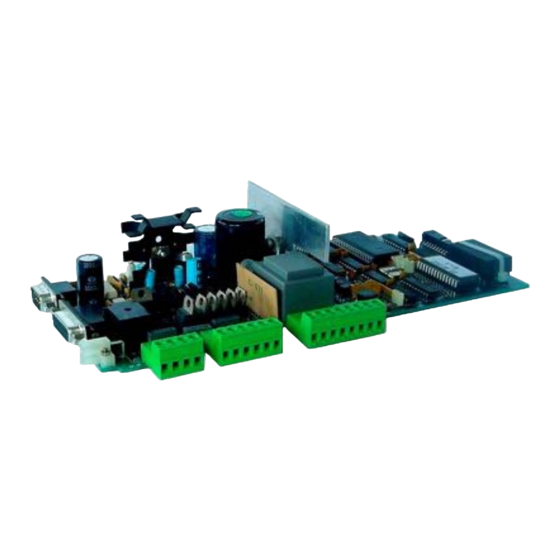

Turbo-V 70 PCB

Controller

Model 969-9508

87-900-871-01 (B)

APRIL 2002

vacuum technologies

MANUALE ISTRUZIONI

BEDIENUNGSHANDBUCH

NOTICE DE MODE D'EMPLOI

MANUAL DE INSTRUCCIONES

MANUAL DE ISTRUÇÕES

BEDRIJFSHANDLEIDING

ISTRUKSTIONSBOG

BRUKSANVISNING

INSTRUKSJON MANUAL

OHJEKÄSIKIRJA

Ο∆ΗΓΙΕΣ ΧΡΗΣΕΩΣ

INSTRUCTION MANUAL

Publicité

Table des Matières

Sommaire des Matières pour Varian Turbo-V 70 PCB

- Page 1 MANUALE ISTRUZIONI Turbo-V 70 PCB BEDIENUNGSHANDBUCH Controller NOTICE DE MODE D’EMPLOI MANUAL DE INSTRUCCIONES Model 969-9508 MANUAL DE ISTRUÇÕES BEDRIJFSHANDLEIDING ISTRUKSTIONSBOG BRUKSANVISNING INSTRUKSJON MANUAL OHJEKÄSIKIRJA Ο∆ΗΓΙΕΣ ΧΡΗΣΕΩΣ INSTRUCTION MANUAL 87-900-871-01 (B) APRIL 2002...

- Page 2 Turbo-V 70 PCB Controller...

-

Page 5: Table Des Matières

BRUGSANVISNING...................... BRUKSANVISNING ...................... BRUKERVEILEDNING....................KÄYTTÖOHJEET......................ODHGIES CRHSEWS...................... INSTRUCTIONS FOR USE ..................TECHNICAL INFORMATION..................TURBO-V 70 PCB CONTROLLER DESCRIPTION ............... CONTROLLER SPECIFICATIONS ....................CONTROLLER OUTLINE..................………………. GENERAL............................POWER INTERCONNECTIONS ....................Controller to Power Connection .................... Connection P6 - 24 Vdc Connector..................LOGIC INTERCONNECTIONS ....................... - Page 6 USE ..............................General..........................Startup........................... FRONT / REMOTE Selection....................Monitor Relay Programming....................Reset Command ........................Starting the Pump........................Operating the Pump ......................Low Speed Operation......................Pump Shutdown ........................Power Failure ........................Remote Control Mode Operation ..................ERROR MESSAGES........................CONTROLLER TEST........................Power Supply Test ........................ Test with Dummy Load......................

-

Page 7: Informazioni Generali

Turbo-V 70 PCB. Il controller pilota le pompe della serie Turbo-V 70 PCB (con un processo suddiviso in dieci passi) durante la fase di avvio controllando la tensione e la corrente in rapporto alla velocità... - Page 8 ISTRUZIONI PER L’USO Cavo di Interconnessione tra il Controller e la Pompa Interconnessioni tra il Controller ed il Trasformatore INSTALLAZIONE NOTA Il controller installato nel sistema definitivo deve essere PERICOLO! posizionato in modo tale che l'aria di raffreddamento possa circolare liberamente intorno all'apparato. Non Le tensioni presenti tra il controller ed il relativo installare e/o utilizzare il controller in ambienti esposti trasformatore, e tra il trasformatore e la rete di...

-

Page 9: Procedure Di Uso

MANUTENZIONE Di seguito è illustrato il pannello di comando dell'hand held terminal. I controller della serie Turbo-V 70 PCB non richiedono alcuna manutenzione. Qualsiasi intervento deve essere eseguito da personale autorizzato. In caso di guasto è possibile usufruire del servizio di riparazione Varian o del "Varian advance exchange service", che permette... -

Page 10: Messaggi Di Errore

Premere due volte il pulsante START per OVERVOLTAGE alimentazione controller, riavviare la pompa. Se il messaggio si controller ha ricevuto un segnale spurio. ripresenta rivolgersi in Varian per la manutenzione. Interruzione fusibile sul secondario di Rivolgersi alla Varian per la Manuten- CONTROLLER FAILURE potenza. -

Page 11: Gebrauchsanleitung

Betrieb zuständigen örtlichen Verkaufsstelle gemeldet werden. Pumpenserie Turbo-V 70 PCB erforderlichen Schaltungen. Der Controller steuert die Pumpen der Serie Turbo-V 70 PCB (durch einen 10-Schritte-Prozeß) in der Startphase, indem er die Spannung und die Stromstärke im Verhältnis Pumpen-geschwindigkeit kontrolliert. - Page 12 GEBRAUCHSANLEITUNG Verbundkabel zwischen Controller und Pumpe Verbundkabel zwischen Controller und Transformator INSTALLATION ANMERKUNG Der im definitiven System installierte Controller muß so GEFAHR! positioniert sein, daß die Kühlungsluft frei um das Gerät zirkulieren kann. Controller darf nicht Die Spannungen auf dem Controller und dem Umgebungen installiert u/o benutzt werden, die zugehörigen Transformator, sowie zwischen dem Witterungseinflüssen (Regen, Frost, Schnee), Staub...

-

Page 13: Bedienung

Schließflansch verschlossen ist. Nachstehend wird die Steuertafel des "Hand Held WARTUNG Terminals" beschrieben. Die Controller der Serie Turbo-V 70 PCB sind wartungsfrei. Eventuell erforderliche Eingriffe müssen von dazu befugtem Fachpersonal ausgeführt werden. Bei einem Defekt kann der Varian-Reparaturdienst bzw. der "Varian... -

Page 14: Fehlermeldungen

Die Pumpe durch zweimalige Betätigung der OVERVOLTAGE Controllers bzw. der Controller hat ein START-Taste neustar-ten. Erscheint falsches Signal erhalten. Meldung wieder sollte der Varian-Wartungs- dienst gerufen werden. CONTROLLER FAILURE Unterbrechung der Schmelzsicherung am Zur Instandhaltung an Varian wenden. sekundären Leistungsstromkreis. 87-900-871-01 (B) -

Page 15: Indications Generales

Turbo-V 70 PCB. Le contrôleur pilote les pompes de la série Turbo-V 70 PCB (selon un processus subdivisé en dix pas) pendant la phase de mise en marche, en contrôlant la tension et le courant par rapport à la vitesse atteinte par la pompe. - Page 16 MODE D'EMPLOI Câble d’Interconnexion entre le contrôleur et la pompe Interconnexions entre le contrôleur et le transformateur NOTE INSTALLATION Le contrôleur installé dans le système définitif doit être positionné de façon à ce que l'air de refroidissement puisse circuler librement autour de l'appareil. Ne pas installer et/ou DANGER! utiliser le contrôleur dans des milieux exposés à...

-

Page 17: Procedures D'utilisation

ENTRETIEN On présente ci-dessous le tableau de commande du “Hand Held Terminal”. Les contrôleurs de la série Turbo-V 70 PCB n'exigent aucun entretien. Toute opération doit être effectuée par un personnel agréé. En cas de panne, il est possible de s'adresser au Service de réparation Varian ou bien au... -

Page 18: Messages D'erreur

Si le message se présente à nouveau, s'adresser à Varian pour l'entretien. Interruption du fusible sur le secondaire Contacter Varian pour l’entretien. CONTROLLER FAILURE de puissance. 87-900-871-01 (B) -

Page 19: Información General

Varian antes de utilizar el equipo. Varian se temperatura: de -20 °C a +70 °C • considera libre de cualquier responsabilidad debida al humedad relativa: 0 - 95% (no condensadora) •... - Page 20 INSTRUCCIONES DE USO Cable de interconexión entre el controler y la bomba Interconexiones entre el controler y el transformador INSTALLACIÓN NOTA El controler instalado en el sistema definitivo ha de ¡PELIGRO! colocarse de manera que el aire de refrigeración pueda circular libremente alrededor del aparato.

-

Page 21: Procedimientos De Uso

MANTENIMIENTO A continuación se ilustra el panel de mando del hand Los controlers de la serie Turbo-V 70 PCB no necesitan held terminal. ningún mantenimiento. Cualquier operación ha de ser efectuada por personal autorizado. En caso de avería es posible utilizar el servicio de reparación Varian o del “Varian... -

Page 22: Mensajes De Error

Si el mensaje se vuelve a presentar dirigirse a Varian para el mantenimiento. Interrupción del fusible sobre el secundario Contactar Varian para el Mantenimiento. CONTROLLER FAILURE de potencia. 87-900-871-01 (B) -

Page 23: Informações Gerais

Turbo-V 70 PCB. O controller comanda as bombas da série Turbo-V 70 PCB (com um processo subdividido em dez passos) durante a fase de activação, controlando a tensão e a corrente em relação à velocidade atingida pela bomba. -

Page 24: Instalação

INSTRUÇÕES PARA O USO Cabo de interconexão entre o controller e a bomba Interconexões entre o controller e o transformador INSTALAÇÃO NOTA O controller instalado no sistema definitivo deve ser PERIGO! posicionado de modo que o ar de refrigeração possa circular livremente ao redor da aparelhagem. -

Page 25: Procedimentos De Uso

A seguir, está ilustrado o painel de comando do “Hand MANUTENÇÃO Held Terminal”. O controller da série Turbo-V 70 PCB não requer qualquer manutenção. Todas as operações devem ser efectuadas por pessoal autorizado. Em caso de defeito é possível utilizar o serviço de reparação Varian ou o "Varian advance exchange service", que permite obter... -

Page 26: Mensagens De Erro

Premer duas vezes o botão START para alimentação do controller, ou o controller reactivar a bomba. Se a mensagem se recebeu um sinal falso. reapresentar, dirigir-se à Varian para a manutenção. Interrupção fusível no secundário de Contactar a Varian para a manutenção. -

Page 27: Algemene Informatie

Turbo-V 70 PCB. De controller stuurt de pompen van de serie Turbo-V 70 PCB (met een proces bestaande uit tien stappen) tijdens de startfase, en controleert hierbij de spanning en de stroom in verhouding tot de door de pomp bereikte snelheid. -

Page 28: Installatie

GEBRUIKSAANWIJZINGEN Verbindingskabel tussen controller en pomp Verbindingskabel tussen controller en transformator INSTALLATIE OPMERKING De controller die definitief in het systeem geïnstalleerd wordt moet zodanig geplaatst worden dat de koellucht GEVAAR! vrij rondom het apparaat kan circuleren. De controller mag niet geïnstalleerd en/of gebruikt worden in ruimten De spanningen aanwezig tussen de controller en de die blootgesteld zijn aan de weersomstandigheden bijbehorende transformator, en tussen de transformator en... - Page 29 Hier volgt de beschrijving van het bedieningspaneel van de hand-terminal. ONDERHOUD De controllers van de serie Turbo-V 70 PCB zijn onderho- udsvrij. Eventuele werkzaamheden moeten door bevoegd personeel worden uitgevoerd. In geval van storing is het mogelijk om de reparatiedienst van Varian of de "Varian advanced exchange service"...

- Page 30 Als de melding weer controller heeft stoorsignaal verschijnt zich voor onderhoud tot Varian ontvangen. wenden. Doorgebrande zekering in secondaire Zich tot Varian voor het onderhoud wenden. CONTROLLER FAILURE hoofdstroomkring. 87-900-871-01 (B)

-

Page 31: Generel Information

Styreenheden kontrollerer pumperne i Turbo-V 70 PCB serien (med en ti-trins- proces) i forbindelse med start. Spænding og strøm reguleres i forhold til pumpens opnåede hastighed. Styreenheden omfatter alle midler, der kræves for automatisk drift af pumperne i Turbo-V 70 PCB serien. - Page 32 BRUGSANVISNING Forbindelseskabel mellem styreenhed og pump Forbindelseskabel mellem styreenhed og transformator INSTALLATION BEMÆRK Styreenheden skal anbringes på en sådan måde, at luft ADVARSEL! kan cirkulerer frit omkring apparatet. Installér og anvend ikke styreenheden i miljøer, der udsættes for Spænding mellem styreenheden og transformatoren påvirkninger fra atmosfæren (regn, sne, is), damp, samt mellem transformatoren og elnettet kan nå...

-

Page 33: Vedligeholdelse

Følgende beskriver manøvrepanelet til hand-held terminalen. VEDLIGEHOLDELSE Styreenhederne i Turbo-V 70 PCB serien behøver ikke nogen vedligeholdelse. Ethvert indgreb på pumpen skal foretages af autoriseret personale. Hvis pumpen går i stykker, kan man benytte sig af Varians reparations- service eller Varian udvekslingsservice, hvor man kan få... - Page 34 Der er opstået fejl i styreenhedens Tryk to gange på START-knappen for at fødespænding eller styreenheden har fået starte pumpen igen. et falsk signal. Hvis meddelelsen kommer igen tag kontakt med Varian for nødvendig vedligeholdelse. Afbrydelse sikring sekundært Ret henvendelse til Varian vedrørende CONTROLLER FAILURE effektkredsløb.

-

Page 35: Allmän Information

åsidosättande instruktionerna, olämplig användning av person utan tillräcklig kunskap, obehörigt bruk av utrustningen eller FÖRBEREDELSER FÖR INSTALLATION hantering som strider mot gällande lokala föreskrifter. Styrenheten i Turbo-V 70 PCB serien är en mikro- Styrenheten levereras särskilt skyddande processorstyrd frekvensomvandlare som består av emballage. - Page 36 BRUKSANVISNING Anslutningskabel mellan styrenhet och pump Anslutningskabel mellan styrenhet och transformator INSTALLATION OBSERVERA Styrenheten ska installeras permanent på ett sådant VARNING! ställe, att kylluften kan cirkulera fritt kring apparaten. Installera och använd inte styrenheten i miljöer som Spänningen mellan styrenhet och transformator samt utsätts för påverkan från atmosfären (regn, snö, is), mellan transformator och elnätet kan nå...

-

Page 37: Instruktioner För Bruk

UNDERHÅLL Nedan beskrivs manöverpanelen för Hand Held Terminalen. Styrenheterna i Turbo-V 70 PCB serien är underhållsfria. Allt servicearbete måste utföras av auktoriserad personal. Om styrenheten havererar, kontakta Varian reparation- sverkstad eller Varian utbytesservice, som kan ersätta styrenheten med en renoverad styrenhet. - Page 38 Tryck två gånger på knappen START för att OVERVOLTAGE uppstått eller styrenheten har fått en falsk starta om pumpen. signal. Om meddelandet visas igen, ta kontakt med Varian för nödvändigt underhåll. Avbrott säkring sekundära Kontakta Varian för underhåll. CONTROLLER FAILURE effektkretsen.

-

Page 39: Generell Informasjon

Når styreenhetene transporteres eller lagres, må brukere. Brukeren bør lese denne brukerveiledningen og følgende forhold være oppfylt: all annen informasjon fra Varian før utstyret tas i bruk. temperatur: fra 20 °C til +70 °C • Varian kan ikke holdes ansvarlig for hendelser som skjer relativ fuktighet:0 - 95% (uten kondens) på... - Page 40 BRUKERVEILEDNING Forbindelseskabel mellom styreenhet og pump Forbindelseskabel mellom styreenhet og transformator INSTALLASJON MERK Styreenheten skal installeres på slik måte, kjøleluften kan sirkulere fritt rundt apparatet. Ikke ADVARSEL! installer eller bruk styreenheten i miljøer som utsettes Spenningen mellom styreenheten og transformatoren for regn, snø...

-

Page 41: Instruksjoner For Bruk

VEDLIKEHOLD Nedenfor beskrives styrepanelet til styreenheten. Turbo-V 70 PCB seriens styreenheter er vedlikeholdsfrie. Alt arbeid på styreenheten må kun utføres av autorisert personell. Dersom styreenheten stanser, må du ta kontakt med Varians reparasjonservice eller med Varians... - Page 42 OVERVOLTAGE Det har oppstått en feil i styreenhetens starte pumpen igjen. Vises feilmeldingen matedel, eller så har styreenheten fått et om igjen, må du ta kontakt med Varian for falskt signal. nødvendig vedlikehold. CONTROLLER FAILURE Avbrudd i sikringen til det sekundæra Kontakt Varian for vedlikehold.

-

Page 43: Yleisiä Tietoja

Valvoja toimitetaan erityisessä suojaavassa Sarjan Turbo-V 70 PCB valvoja on mikroprosessorin pakkauksessa. Mikäli havaitsette mahdollisesti kuljetuksen valvoma kiinteistä materiaaleista tehtyjä aikana sattuneita vaurioita, ottakaa yhteys paikalliseen taajuudenmuuntimia, jotka kykenevät itsemäärittelyyn ja myyntitoimistoon. - Page 44 KÄYTTÖOHJEET Valvojan ja muuntajan litoskaapeli Valvojan ja muuntajan litäntä ASENNUS HUOM Valvojan sisällä syntyy korkeajännitettä, joka voi VAARA! aiheuttaa vakavia vammoja tai jopa kuoleman. Ennen minkätahansa valvojan huolto-tai asennustoimenpiteen Valvojan ja muuntajan välille ja myös muuntajan ja suorittamista, irroittakaa valvoja sähköverkosta.

- Page 45 Mahdolliset valvojaan tehtävät toimenpiteet tulee jättää aina valtuutetun henkilön tehtäviksi. Toimintahäiriön sattuessa on mahdollista käyttää Varianin korjauspalvelua tai "Varian advance exchange service" -palvelua, jolloin on mahdollista vaihtaa rikkoontunut valvoja ladattuun valvojaan. VAARA! Ennen minkätahansa valvojaan tehtävän toimenpiteen suorittamista irroittakaa sähkökaapeli pistorasiasta.

-

Page 46: Vianetsintä

Valvojan sähkövirran syötössä on ilmennyt Painakaa painonappia START kaksi kertaa, OVERVOLTAGE ongelma tai valvojan saama signaali on jolloin pumppu käynnistyy. Mikäli viesti näkyy väärä. uudelleen kääntykää Varian huoltopalvelun puoleen. CONTROLLER FAILURE Sulake palanut toisiovirtapiirissä. Ota yhteys Varianiin huoltoa varten. 87-900-871-01 (B) -

Page 47: Odhgies Crhsews

Ç eiv n ai exoplismev n oÇ miv a euruv c wrh Oi ruqmistev Ç thÇ seirav Ç Turbo-V 70 PCB eiv n ai ev n aÇ prostateutikhv suskeuasiv a . upav r coun endeiv x eiÇ blav b hÇ pou qa mporouv s an na ev c oun proklhqeiv katav th metatropev a Ç... - Page 48 ODHGIES CRHSEWS Sundev s eiÇ metaxuv tou ruqmisthv kai thÇ antliv a Ç Sundev s eiÇ metaxuv tou ruqmisthv kai tou Metaschmatisthv EGKATASTASH SHMEIWSH O ruqmisthv Ç pou ev c ei egkatastaqeiv sto telikov suv s thma qa prev p ei na topoqethqeiv me tev t oio trov p o wv s te o aev r aÇ KINDUNOS yuv x hÇ...

- Page 49 Hand Held Terminal, patwv n taÇ to koumpiv STOP. SUNTHRHSH Oi ruqmistev Ç thÇ seirav Ç Turbo-V 70 PCB den apaitouv n kamiv a sunthv r hsh. Opoiadhv p ote epev m bash qa prev p ei na pragmatopoihqeiv apov exousiodothmev n o proswpikov .

- Page 50 Varian gia sunthv r hsh. Apeuqunqeiv t e sth Varian gia th sunthv r hsh. CONTROLLER FAILURE Diakophv asfav l eiaÇ...

-

Page 51: General Information

Turbo-V 70 PCB pump office. series. The controller drives (within ten steps) the Turbo-V 70 PCB pump during the starting phase by controlling the voltage and current respect to the speed reached by the pump. Remote start/stop, pump status signals, forepump start/stop, interlock control (for pressure switch, water flow switch, etc.) capability, are provided via auxiliary... - Page 52 INSTRUCTIONS FOR USE Interconnection Cable Controller - Pump Interconnection Cable Controller - Power Transformer INSTALLATION NOTE The controller installed into the customer system must be positioned so that cold air can flow through the PCB WARNING! components. Do not install or use the controller in an environment Voltages between controller and power transformer and exposed to atmospheric agents (rain, snow, ice), dust, transformer and mains are dangerous in case of...

-

Page 53: Use Procedure

The Turbo-V 70 PCB series controller does not require any maintenance. Any work performed on the controller must be carried out by authorized personnel. When a fault has occurred it is possible to use the Varian repair service. Replacement controllers are available on an advance exchange basis through Varian. -

Page 54: Error Messages

Press the START push-button twice to start OVERVOLTAGE faulty, or the Controller received a spike. the pump. Should the message still be present, call the Varian service. CONTROLLER FAILURE Fuse blown power supply Contact Varian for Maintenance. secondary of the transformer. 87-900-871-01 (B) -

Page 55: Technical Information

TECHNICAL INFORMATION Moreover, manages signals from sensors, TURBO-V 70 PCB CONTROLLER input/output connection information, and gives outputs DESCRIPTION for a fully automatic operation. The controller is a solid-state frequency converter which is driven by a single chip microcomputer and is... -

Page 56: Controller Specifications

47 to 63 Hz Frequency 350 VA maximum Power CONTROLLER OUTLINE Output: 54 Vac nominal ±10%, Voltage The outline dimensions for the Turbo-V 70 PCB 3-phase controller are shown in the following figure. Frequency 1250 Hz, ±2% Power 150 W maximum Operating 0 °C to +40 °C... -

Page 57: General

TECHNICAL INFORMATION GENERAL POWER INTERCONNECTIONS Inspect the controller for any shipping damage. Controller to Power Connection Before installing the controller you must prepare some The power supply from the external transformer must interconnection cables, i.e. the power interconnections, be connected to J10 and J8 connectors. the logic interconnections and the pump connection. -

Page 58: Connection P6 - 24 Vdc Connector

When the contact is closed, the turbopump and the interconnected devices are stopped. NOTE Pin 3-8 must be shorted to allow the Turbo-V 70 PCB pump to start if no interlock contact is connected. If, after starting the pump, the interlock contact opens, it has no effect on the operation and the pump continues to turn. -

Page 59: Connection J2 - Logic Output Interconnections

TECHNICAL INFORMATION Connection J2 - Logic Output Interconnections DESCRIPTION 7-14 R2 signal 24 V, 60 mA, optically isolated output (pin 14 positive, pin 7 negative). The output Voltage will be present upon the programmed condition delay YES or delay NO (see the cycle diagram in the following pages). -

Page 60: Controller-To-Pump Connection

TECHNICAL INFORMATION Controller-to-Pump Connection To connect the controller to the pump an appropriate interconnection cable must be prepared to connect the J9 terminal board of the controller with the pump connector. The following figure shows the pump output connector configuration where pins: Pins A-F = pump temperature sensor •... -

Page 61: Use

TECHNICAL INFORMATION Startup Plug the controller power cable into a suitable • General power source. Make all vacuum manifold and electrical connections and The display lights, and shows: • refer to Turbo-V pump instruction manual before to operating the Turbo-V controller. R E A D Y F O R L O C A L... -

Page 62: Front / Remote Selection

TECHNICAL INFORMATION Press the CURRENT push-button and the display Press the the CYCLE NUMBER twice and the display • • shows: shows: 0 0 A X X X X C Y C L E X X X X X m K R P M X X °... -

Page 63: Monitor Relay Programming

TECHNICAL INFORMATION After pressing the PUMP CURRENT the second time, the display will be as shown in the following NOTE figure. The Soft Start mode may be deselected/selected only when the pump is stopped. R U N - U P I M E S E L X X h... - Page 64 TECHNICAL INFORMATION By pressing the CYCLE NUMBER pushbutton, selectYES if relay R2 must operate only after the run- up time or select NO when the R2 operation is needed right from start of the turbopump and after the rotational speed of the turbopump exceeds for the first time the speed threshold value as shown in the following figure.

-

Page 65: Reset Command

TECHNICAL INFORMATION Reset Command Press the START push-button (or use the remote • start signal), the display shows: The display shows: • S O F T S T A R T P U M P X X X X X h R E S E T ? X X X where:... -

Page 66: Operating The Pump

TECHNICAL INFORMATION Operating the Pump If the Soft Start mode has been deselected the display • will change and shows: After the starting period, if the system has a vacuum leak or the pressure in the pump/chamber is high (from 1 mbar to atmosphere), the pump continues to operate P U M P S T A R T... -

Page 67: Low Speed Operation

TECHNICAL INFORMATION Low Speed Operation If the Soft Start has been deselected the display shows: P U M P R E A D Y P U S H NOTE S T A R T B U T T O N With the FRONT panel operation selected, the remote and RS 232 operations are inoperative;... -

Page 68: Pump Shutdown

TECHNICAL INFORMATION Pump Shutdown Remote Control Mode Operation Press the front panel STOP pushbutton or remove the If remote signals are used to operate the controller, it remote signal; the power from the turbopump will be must be programmed for remote operation (see removed and the pump will begin to slow down. -

Page 69: Error Messages

TECHNICAL INFORMATION Verify that systems has leaks than press ERROR MESSAGES STOP RESET pushbutton twice to start the pump. For a certain type of failure, the controller will self- diagnose the error and the following messages will be NOTE displayed if the hand-held terminal is connected. If the upper bearing/pump temperature exceeds 60 °C, the pump is shut off, and the display will be as shown NOTE... -

Page 70: Controller Test

On the hand held terminal, push the START Since no operation can be carried out, contact pushbutton and check: VARIAN. − 54 Vdc ±10% between TP3(-) and TP5(+) − 24 Vdc ±15% on the fan connector. b) AC three-phase output voltage test On the pump connector connect the DVM in turn between: pins B and C, B and D, C and D. -

Page 71: Test With Dummy Load

TECHNICAL INFORMATION Test with Dummy Load Pump over-Temperature Test − Connect the 48Ω or the 78Ω dummy loads to the − Disconnect the potentiometer, set it to 5KΩ, and pump connector pins B, C, D, as shown in the then reconnect it. previous figure. -

Page 72: Accessories And Spare Parts

TECHNICAL INFORMATION ACCESSORIES AND SPARE PARTS DESCRIPTION PART NUMBER P2 output mating connector 969-9852 J1 input mating connector 969-9853 OPTIONS DESCRIPTION PART NUMBER Power transformer 969-9862 87-900-871-01 (B) - Page 73 TECHNICAL INFORMATION 87-900-871-01 (B)

-

Page 74: Customer Information

NOTE: If a product is received at Varian which is contaminated with a toxic or hazardous material that was not disclosed, the customer will be held responsible for all costs incurred to ensure the safe handling of the product, and is liable for any harm or injury to Varian employees as well as to any third party occurring as a result of exposure to toxic or hazardous materials present in the product. - Page 75 Request for Return FAILURE REPORT TURBO PUMPS and TURBOCONTROLLERS POSITION PARAMETERS Power: Rotational Speed: Does not start Noise Vertical Current: Inlet Pressure: Does not spin freely Vibrations Horizontal Temp 1: Foreline Pressure: Does not reach full speed Leak Upside-down Mechanical Contact Overtemperature Other: Temp 2:...

- Page 76 Tel: (39) 011 997 9111 Tel: (39) 011 997 9111 Fax: (39) 011 997 9350 Brazil Fax: (39) 011 997 9350 Varian Industria e Comercio Ltda. Japan Avenida Dr. Cardoso de Mello 1644 Internet Users: Varian Vacuum Technologies Vila Olimpia Customer Service &...